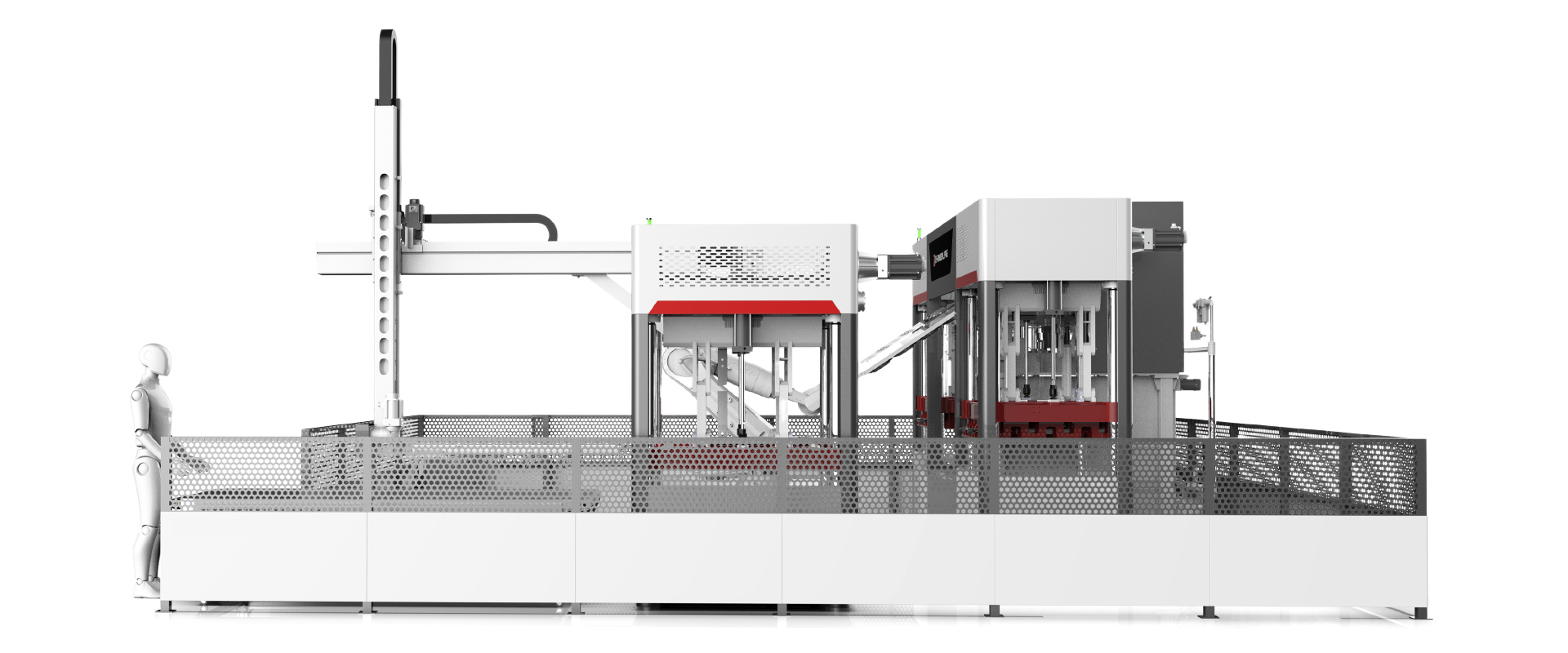

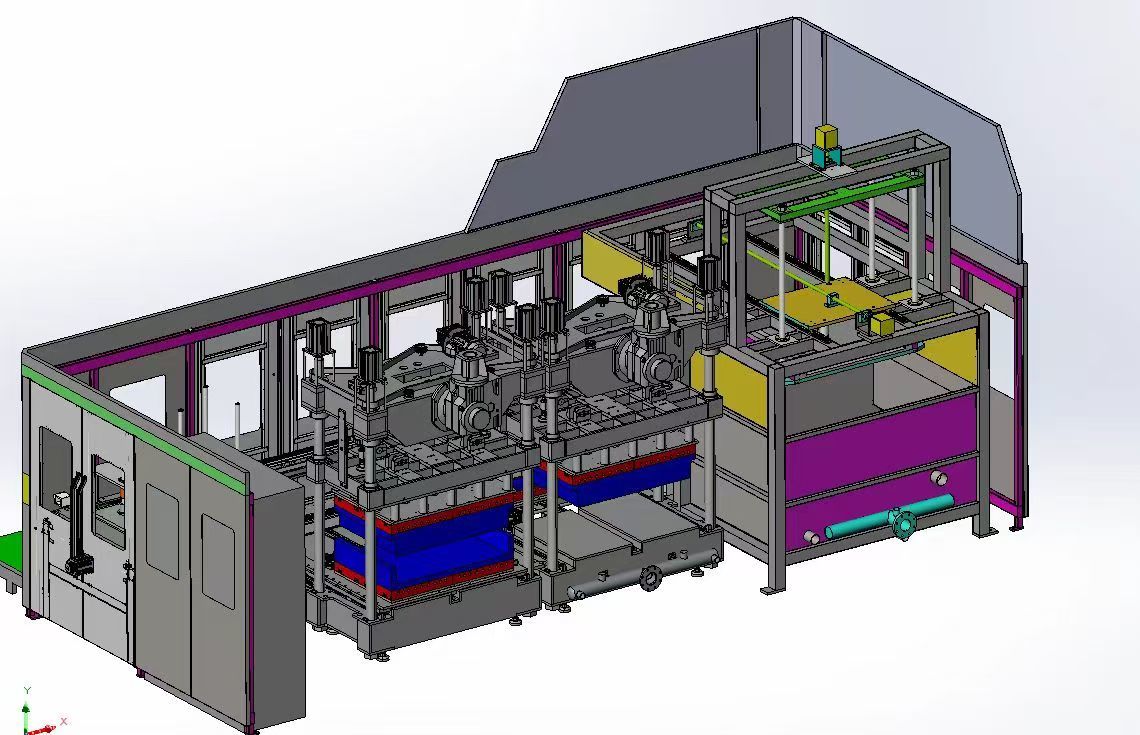

Tableware machine

Product Introduction

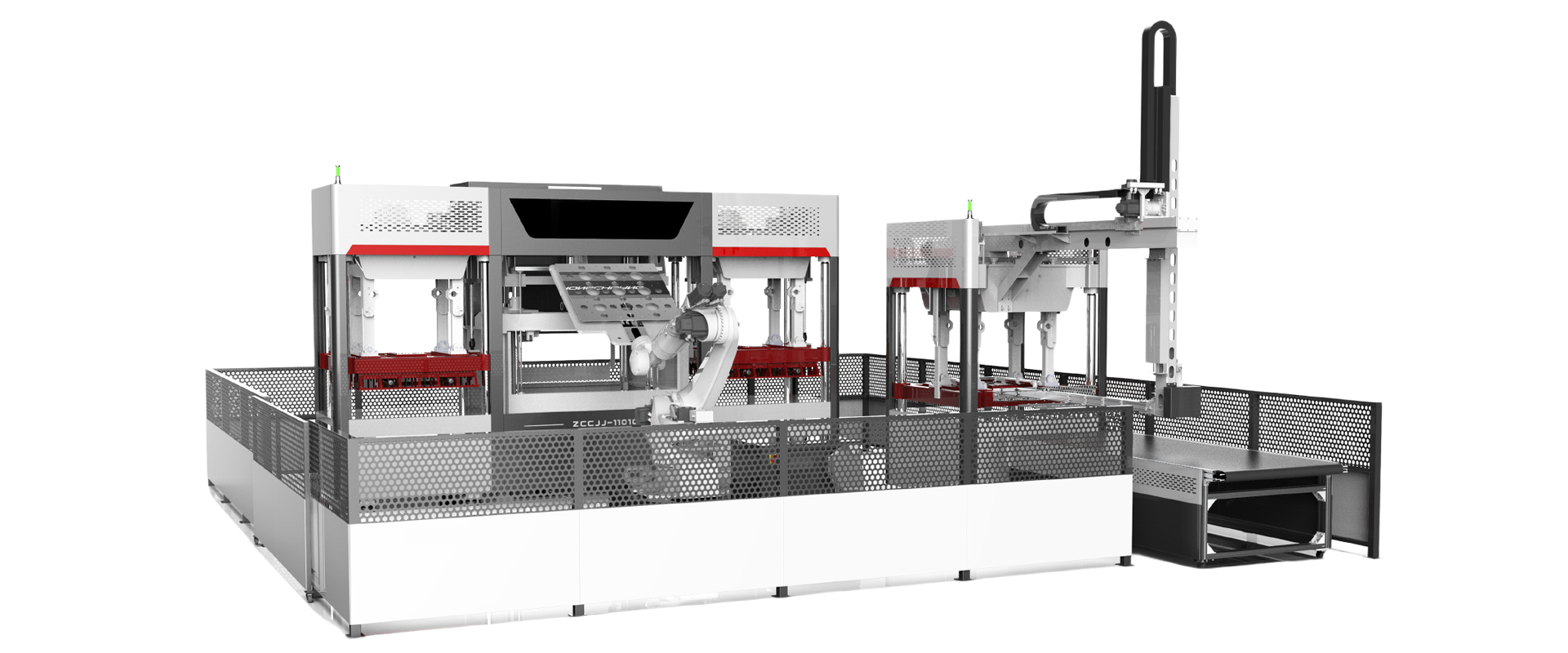

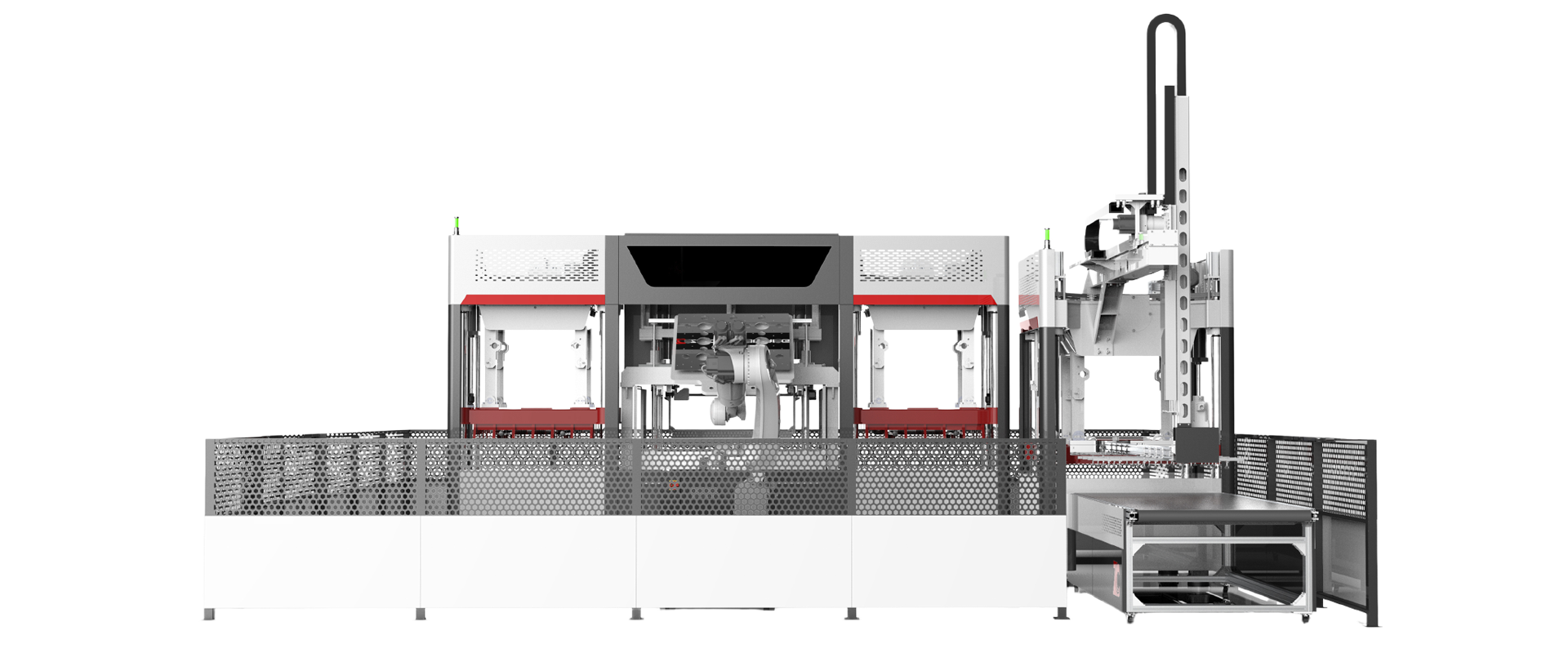

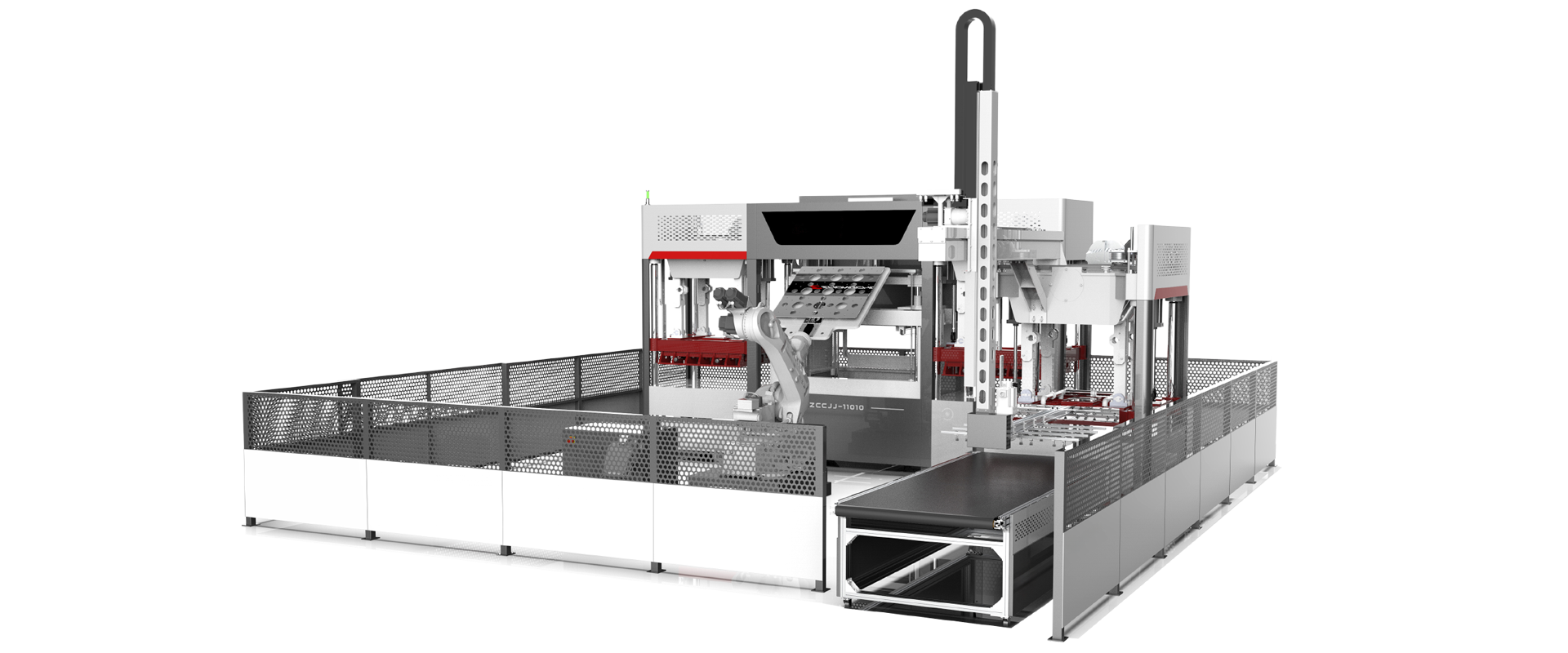

The fully automatic robot intelligent tableware machine has the advantages of precise control, flexible, precise, and stable production operation, with a single machine output of 900-1100kg/d. It is mainly suitable for producing disposable pulp molded tableware, plates, food boxes, high-end industrial shock resistant packaging and other products. The main features of this machine are:

◆ Adopting Siemens intelligent control system, the production operation is flexible, precise, stable, safe to operate and maintain, and simple

◆ Adopting a joint control mode of robot controllers to ensure long-term, efficient, flexible and safe production operation;

◆ New heat supply and energy storage structure design, high yield and low energy consumption, fully optimized production performance;

◆ Adopting Siemens PROFINET communication method to achieve remote intelligent production monitoring and grasp the overall production situation;

◆ The deep integration of production equipment and production technology brings higher quality appearance and quality to products.

Parameters

| Main Parameters | Main Indicators | Main Parameters | Main Indicators |

| Machine Composition | - 6 - axis robot (1 unit) - Servo reciprocating forming machine (1 unit) - Servo linkage hot press (2 units) - Servo linkage trimming machine (1 unit) - Servo truss stacking machine (1 unit) |

Maximum Height of Produced Products / mm | 120 |

| Template Size (mm*mm) | 1100*1100 | Product Transfer Method | Automatic transfer by external robot |

| Molding Method | Slurry - fishing molding | Maximum Trimming Pressure / t | 80 |

| Heating Method | Electric heating/Heat - conducting oil/Steam | Control Method | Siemens PLC + KUKA robot controller |

| Hot Press Pressure / t | 100 | Designed Capacity / (kg/d) | 900 - 1100 |

Keywords:

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote