Egg Box Prduction Line

Product Introduction

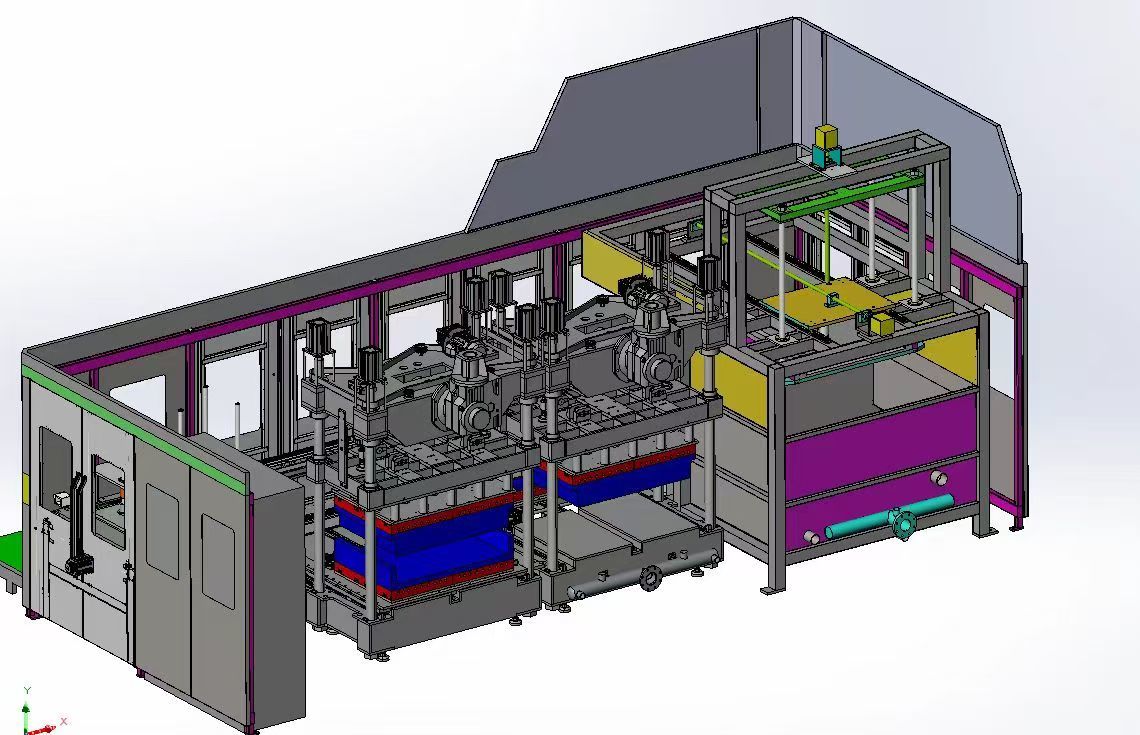

Introduction: The working principle of the rotary drum forming machine is to send the prepared slurry to the slurry tank of the forming machine through the slurry pump. The rotary drum machine is started to operate, and the forming mold keeps rotating with the rotary drum. When the slurry level reaches, the vacuum suction valve is opened to suck the slurry. When the forming mold rotates to release the slurry, the pulp is adsorbed onto the mold mesh through vacuum filtration to form a wet paper mold base. The wet paper mold continues to dehydrate during the rotation of the drum, while hot air is sent from the upper cover for preheating. When the wet paper mold is transferred to the transfer position with the rotation of the drum, the transfer mold and the forming mold are closed. Compressed air is blown into the forming mold and the transfer mold is evacuated to transfer the wet paper mold, and then the transfer mold rotates 90 ° to a horizontal position to blow the product onto the receiving tray, completing one work cycle cycle. The duration and various actions of inhalation, dehydration, and transfer are all controlled by a reducer, converter, and precision divider.

Parameters

| Main Parameters | Main Indicators |

| Model | |

| Maximum Force/t | 80 |

| Pressure Type | Servo Connecting Rod |

| Feeding Method | Servo Truss |

| Material Taking Method | Servo Screw |

| Production Beat/s | 9 - 10 |

| Air Pressure/mpa | 0.5 - 0.7 |

| Vacuum Pressure/mpa | -0.05 - 0.07 |

| Equipment Power/kw | 51 |

| Overall Dimensions/mm | 11504*1870*2500 |

| Weight of the Whole Machine/t |

Keywords:

Finished product display

Finished product display

Finished product display

Finished product display

Finished product display

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote