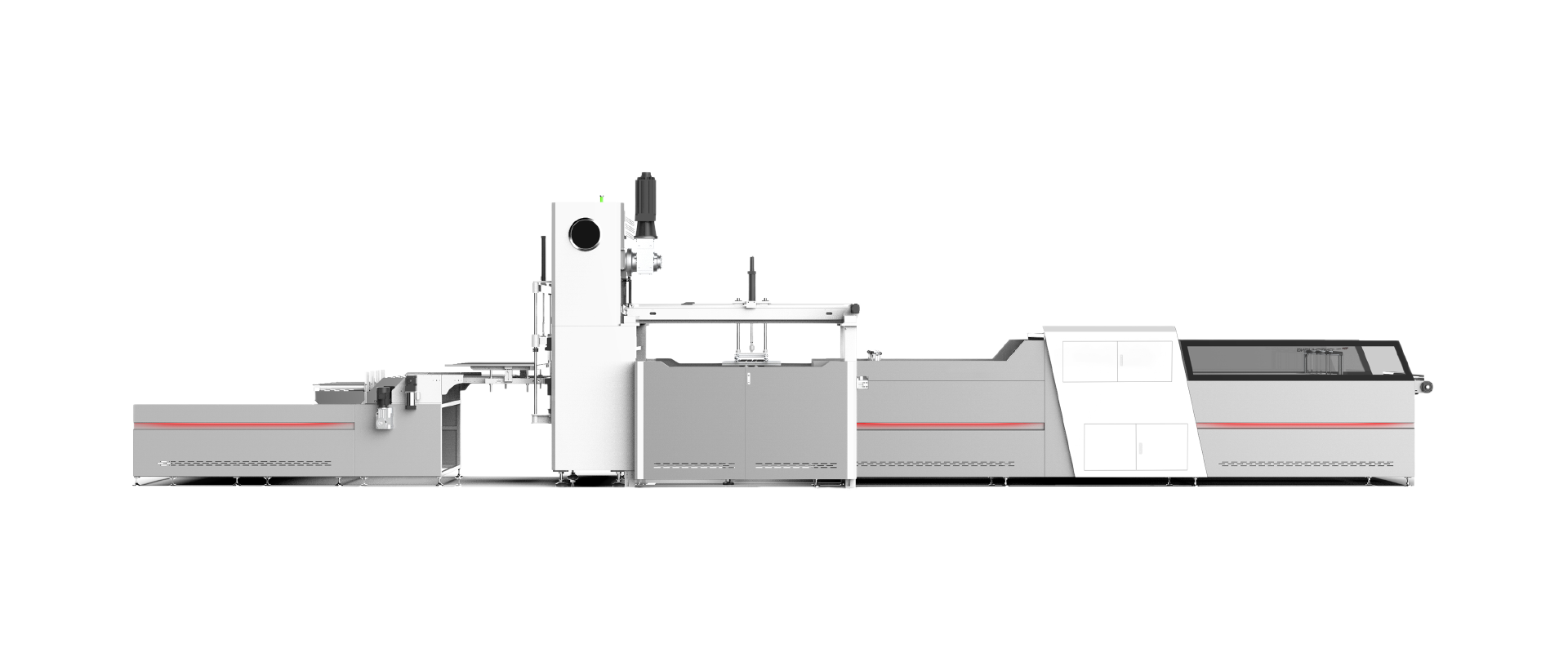

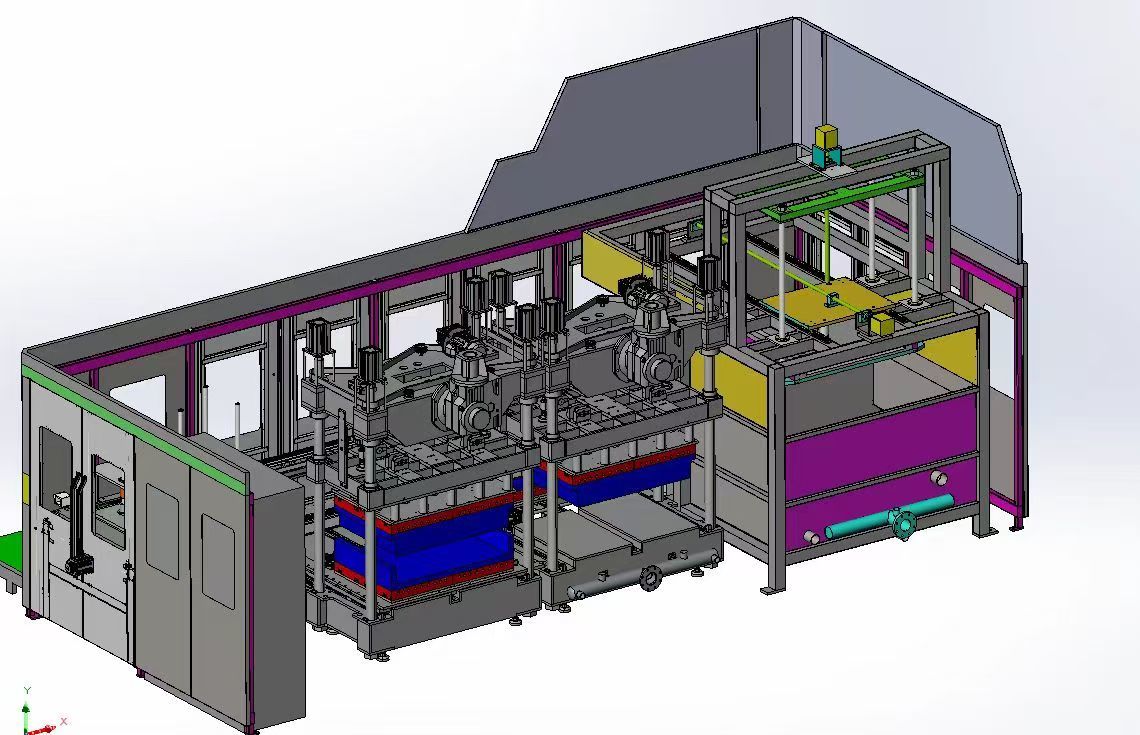

Hot Pressing Forming Line

Product Introduction

The Hot Pressing Forming Line from Fuzhou Huikong uses a servo connecting-rod hot-press method for high-speed, high-precision forming with uniform pressure and a 99% product qualification rate. Its output reaches up to 2,280 pieces per hour—about five times that of traditional manual hot presses—offering safe, reliable, and efficient production for molded products.

The equipment adopts the servo connecting rod hot pressing + removal method, featuring high speed, high precision, uniform pressure, and a product qualification rate of 99%. Its production capacity is five times that of traditional manual hot presses, reaching 2,280 pieces (12 pieces) per hour. It is convenient to use, safe and reliable.

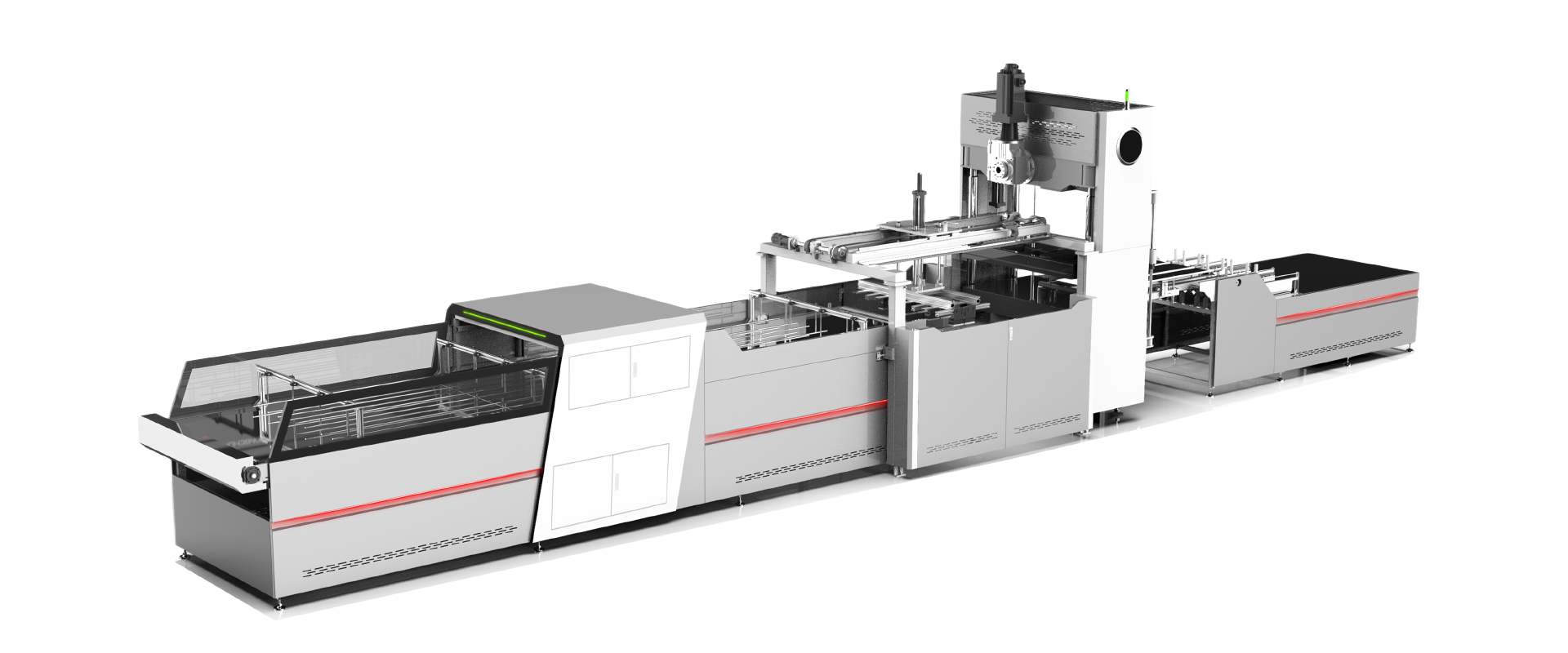

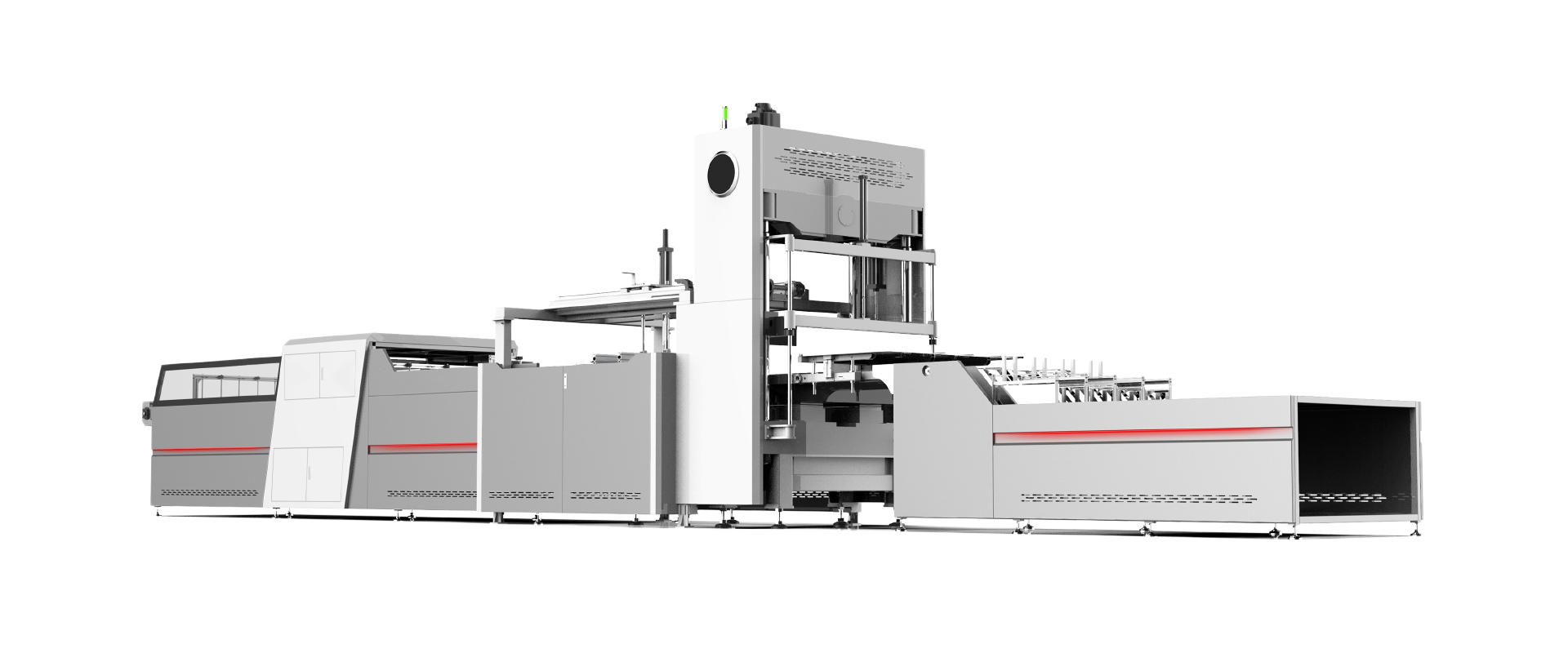

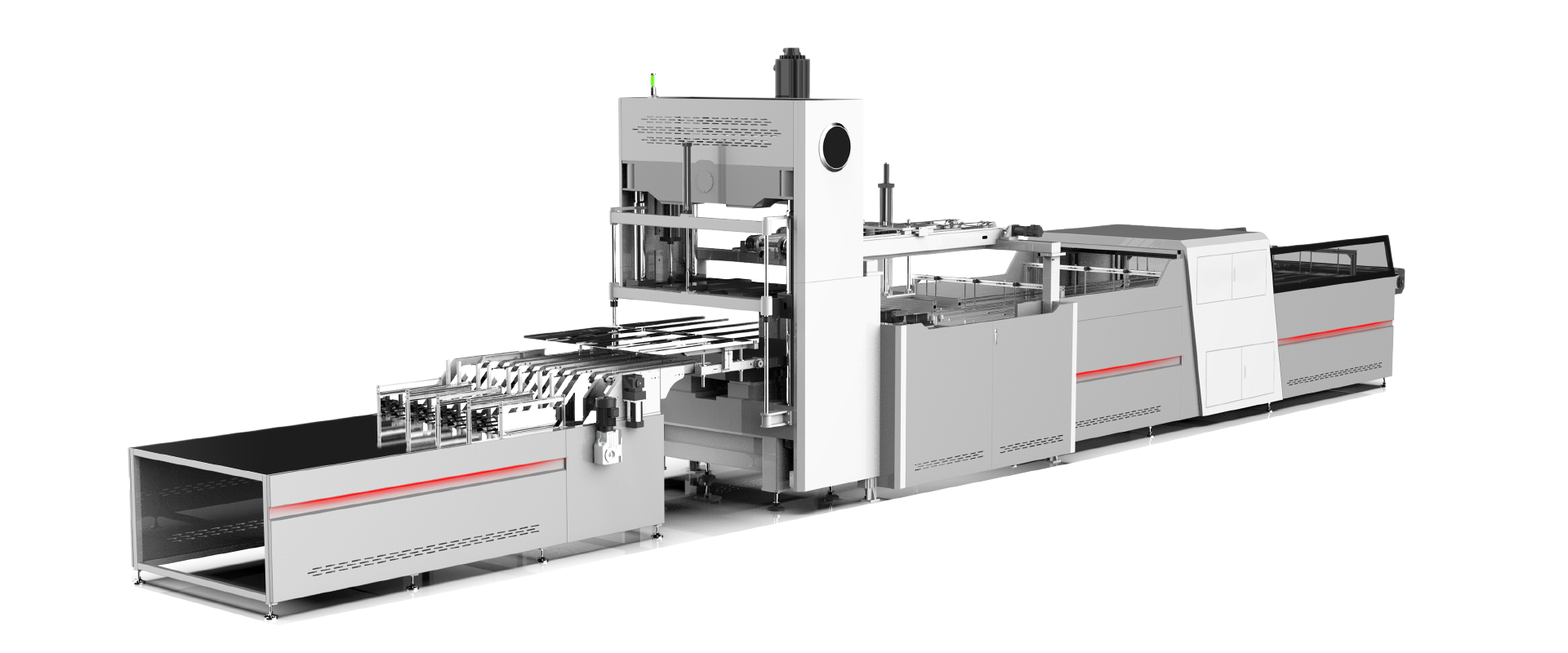

Equipment operation process flow

◆ Conveyor line After the workers put the products into the feeding port, the conveyor line gradually conveys them to the feeding truss in a step-by-step manner

◆ Humidification device By using high-pressure spray technology, water mist is directly sprayed onto the surface of the products to prevent them from getting damp, making them hot-pressed flat and smooth, and meeting the standards for use in the next process.

◆ Feeding mechanism It is responsible for transporting the products from the conveyor line to the workstations to the lower mold cavity of the setting machine. Moreover, the suction cup position is equipped with a shaped pressure plate. When placing the products, the shaped pressure plate gently presses the products to the 1/3 position of the mold cavity, thus achieving the purpose of accurately placing them into the mold and improving the product qualification rate.

◆ Extraction-type setting machine After the feeding mechanism places the product into the lower die cavity, the lower die quickly moves into the machine body. The hot pressing process is completed by setting the hot pressing time, as well as the blowing and pumping times, etc.

◆ Blocking sorting mechanism There are eight products at a time. Four double-row products enter the blocking sorting mechanism. Through the acceleration, blocking, sorting and other actions of the mechanism, the products enter the stacking mechanism in an orderly manner.

◆ Stacking mechanism When the products of the blocking sorting mechanism enter the mechanism, the mechanism automatically stacks the products in an orderly manner.

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote