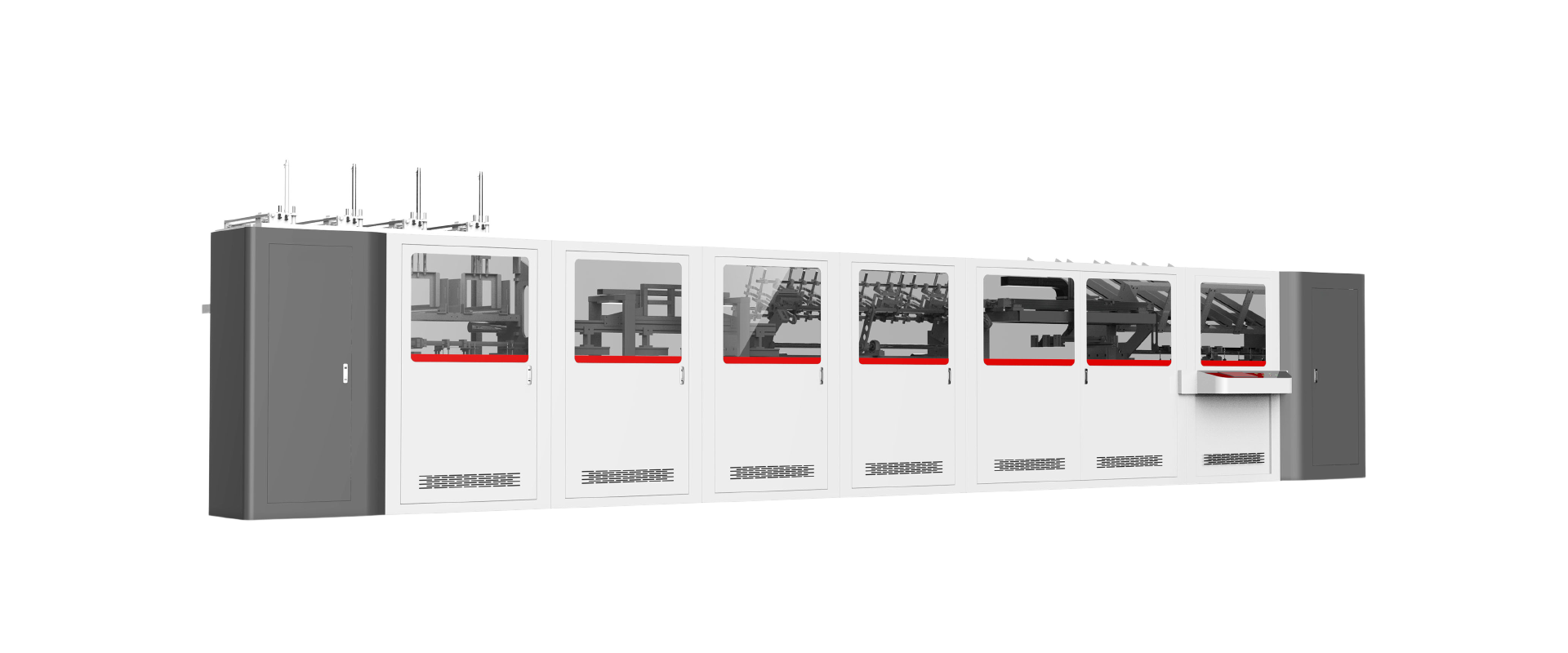

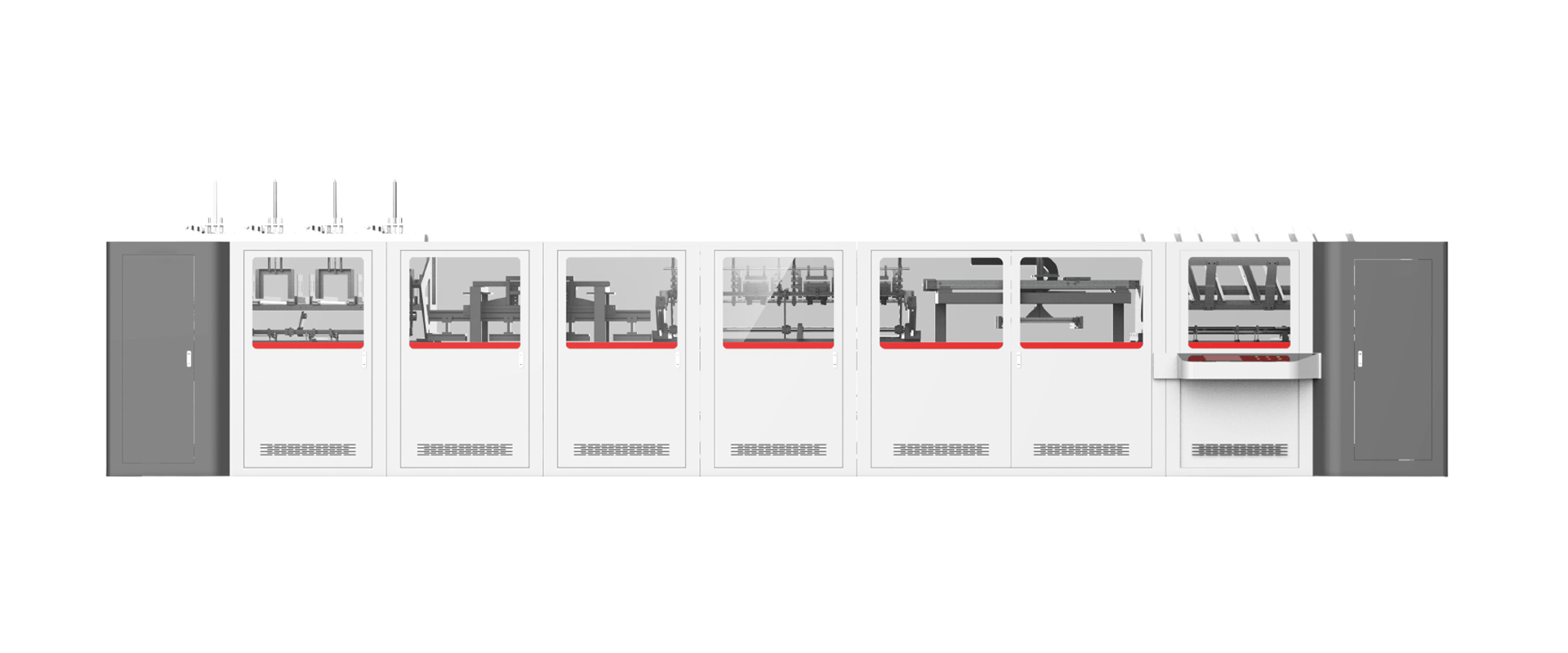

Labeling Machine

Product Introduction

The equipment adopts a servo+mechanical transmission mode, with a simple mechanical mechanism, easy operation, and high degree of automation. It can label 2 products (10 or 12 pieces) at the same time. It uses advanced low-pressure spraying technology to achieve multi-point positioning and continuous spraying of glue on the egg box, making the glue spraying on the egg box uniform without overflowing. The whole machine has fast speed, high accuracy, low noise, low glue consumption, and can label 60 pieces per minute. The nozzle has good atomization performance, is not easy to block, and can adapt to long-term operation. It is one of the ideal equipment for egg box labeling.

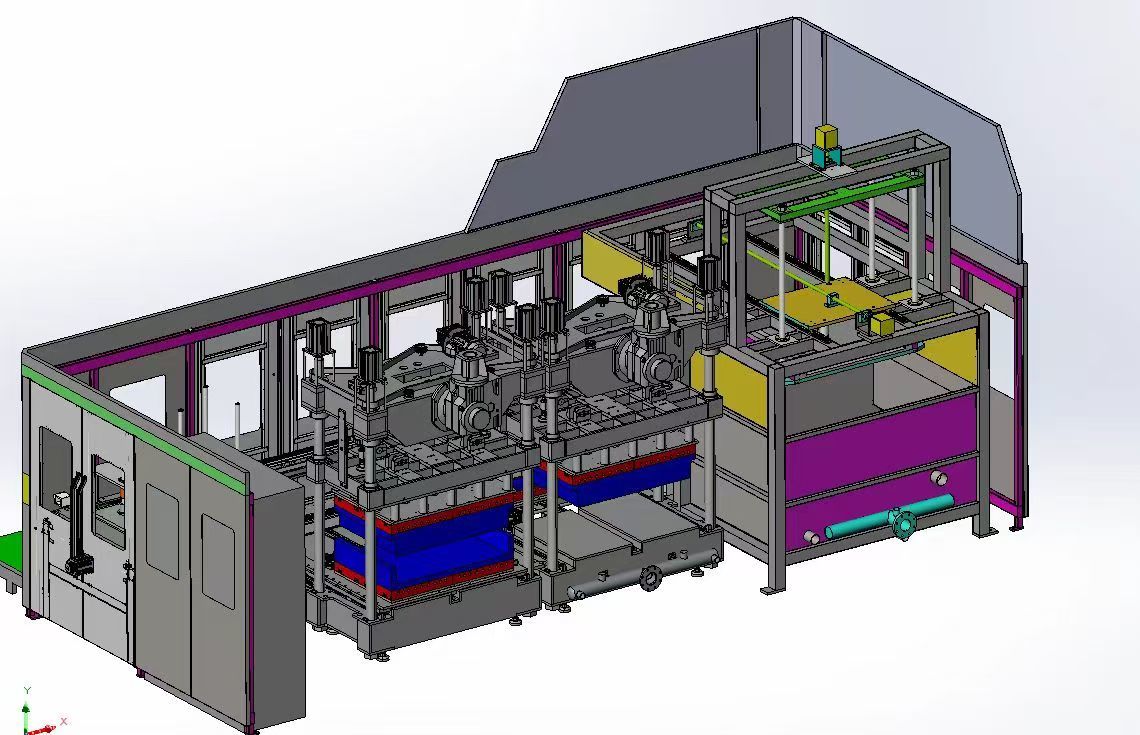

Parameters

| Main Parameters | Main Indicators |

| Model | ZCQBJ-8060 |

| Maximum Output/t | 50 |

| Pressure Type | Servo Connecting Rod |

| Feeding Method | Servo Truss |

| Material Taking Method | Servo Truss |

| Production Cycle/s | 7-9 |

| Air Pressure/mpa | 0.5-0.7 |

| Vacuum Pressure/mpa | -0.05-0.07 |

| Equipment Power/kw | 9 |

Keywords:

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote