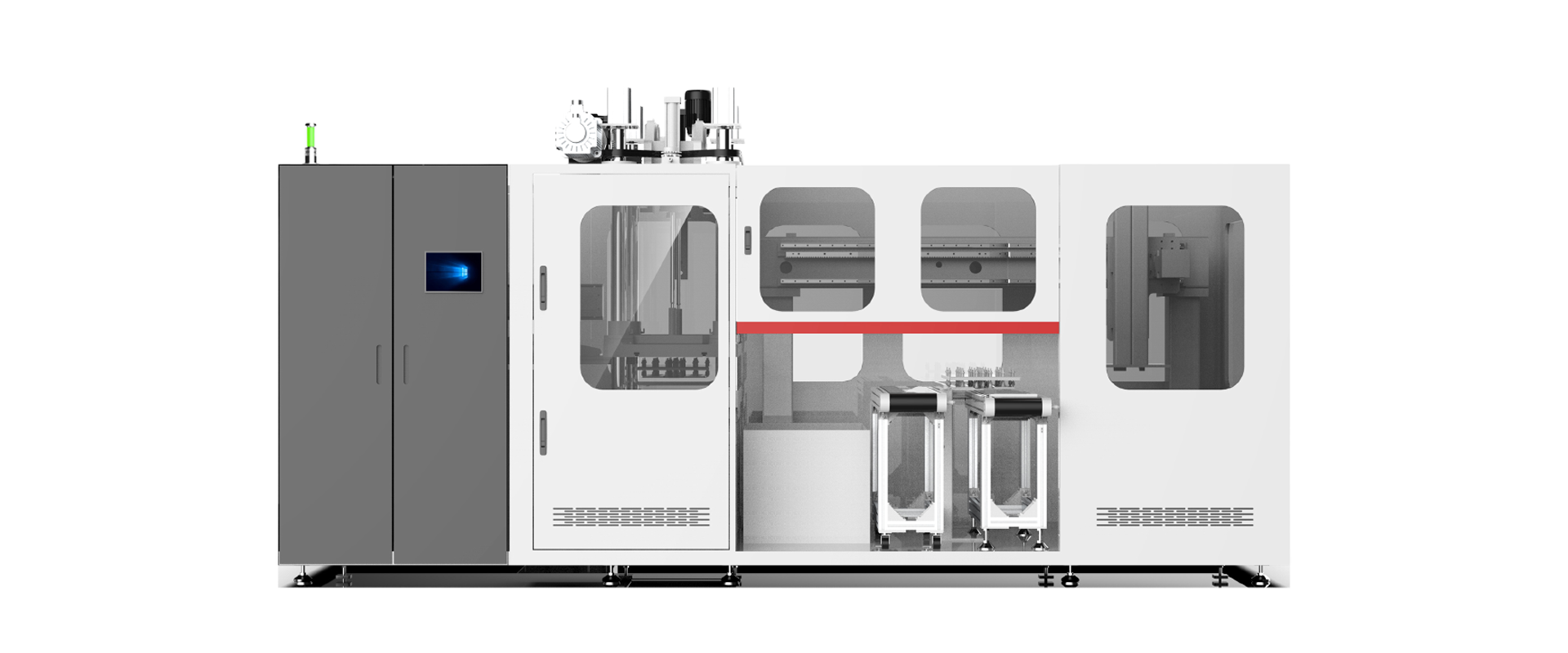

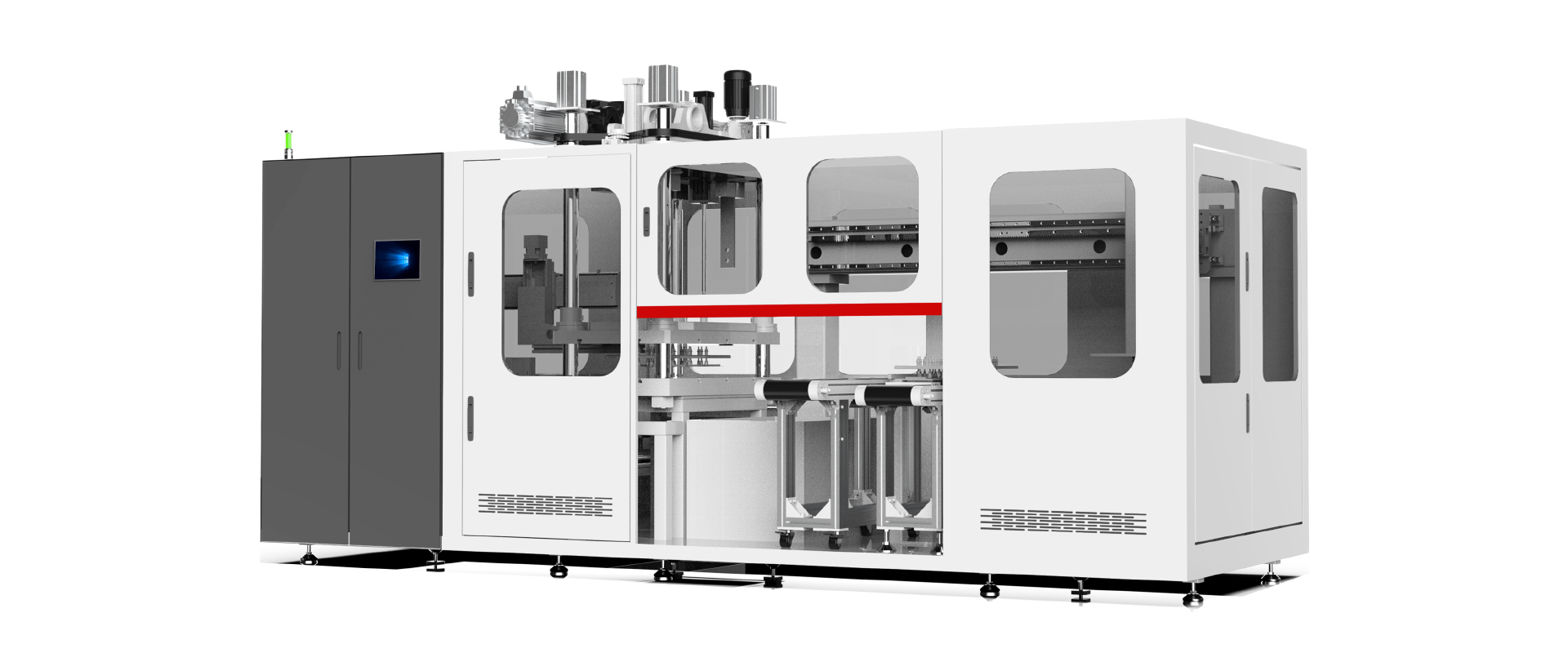

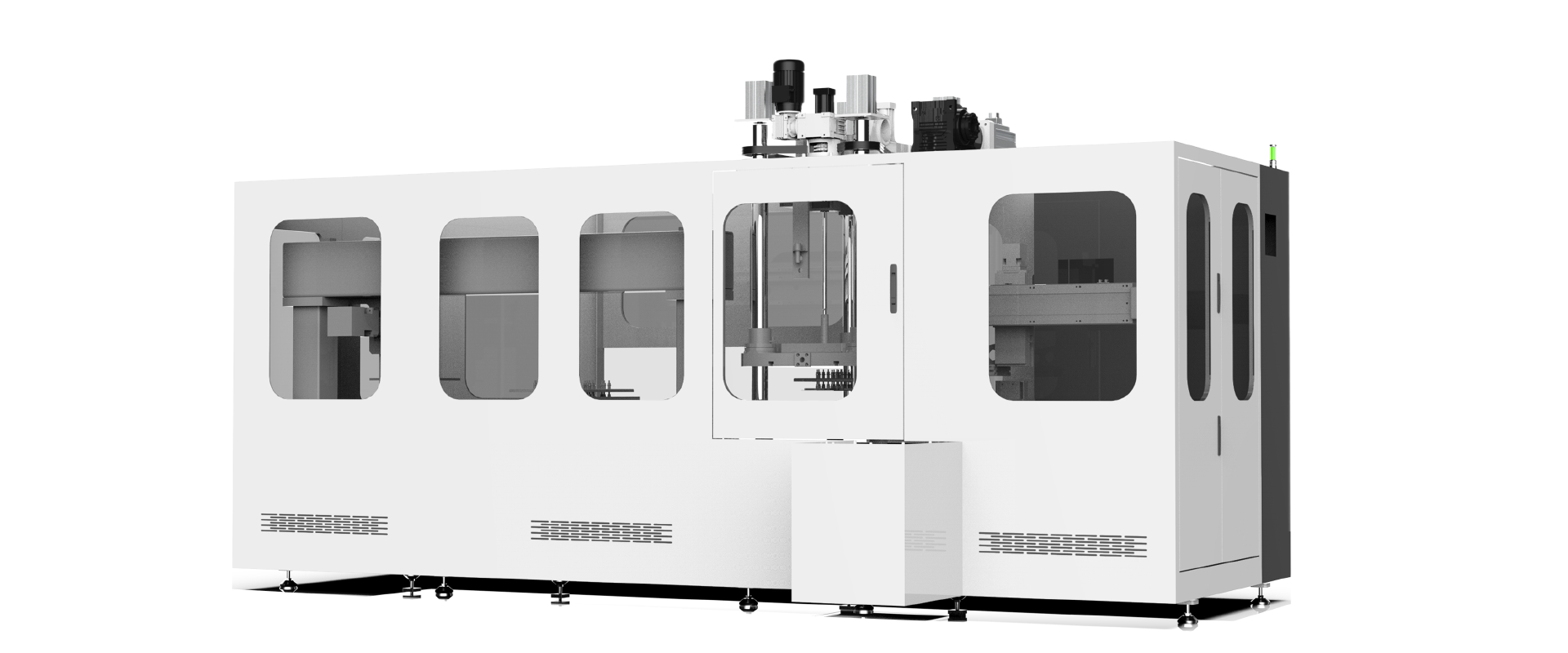

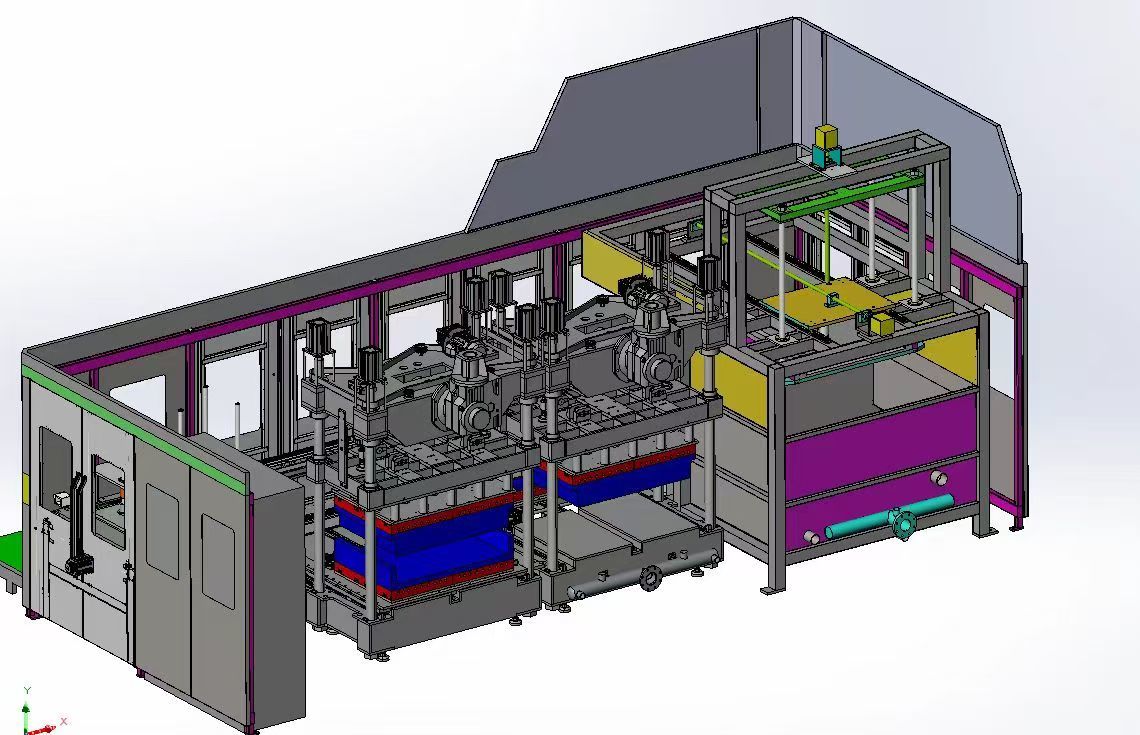

Edge-Cutting Stacker

Product Introduction

The whole machine adopts a fully servo control system, which is fast in speed and high in accuracy. The edge cutting machine uses a servo linkage mechanism to operate, automatically lubricate and lubricate, and digitally adjust the mold opening height and closing height. Due to the use of digital position cutting, it effectively protects and extends the service life of the cutting die.

Process flow

The product is placed in the feeding platform. When the feeding platform senses the presence of the product, it automatically moves to the feeding mechanism, which automatically sends the product to the feeding position. The feeding truss Z-axis and X-axis run automatically to feed the product into the edge cutting mold. The edge cutting machine runs automatically to cut the edge. After the edge cutting is completed, the stacking truss automatically enters the edge cutting machine to grab the waste edges and products, and then moves them out. The waste edges are placed in order first, and then the products are stacked. When the product reaches a certain quantity, the conveyor line automatically sends the product out for inspection or packaging.

Keywords:

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote