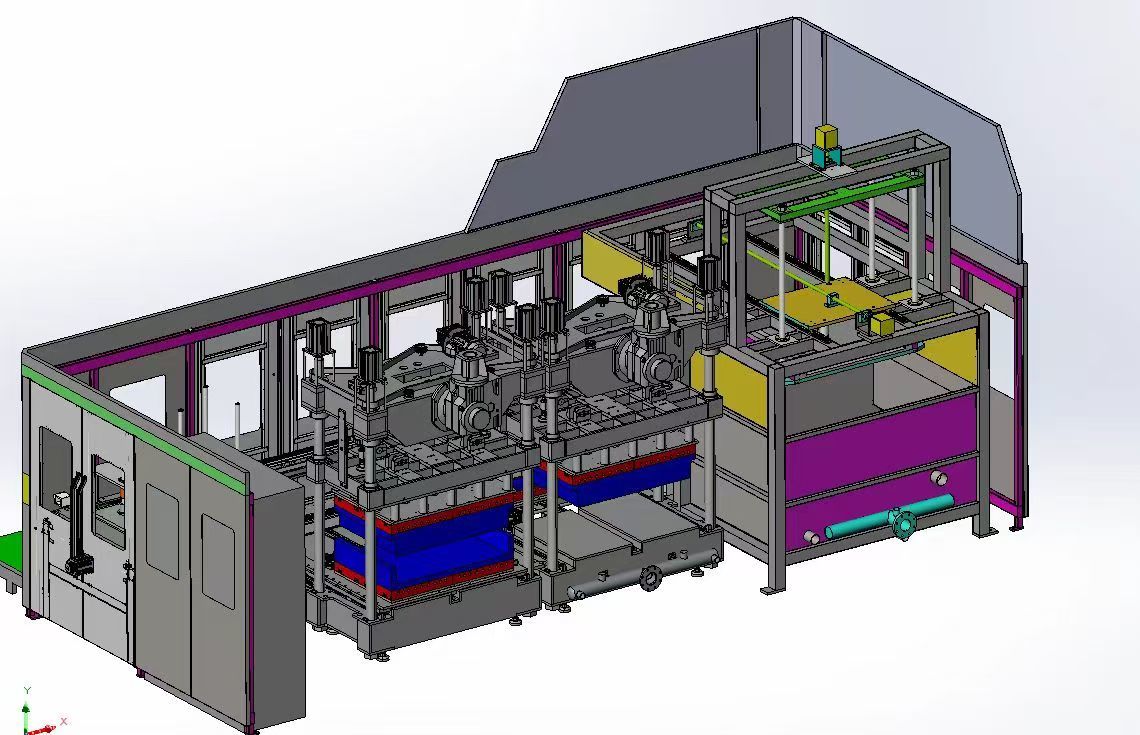

Egg carton inner printing machine

Product Introduction

Product description and feature

◆ High-speed and efficient printing: 50-60 pieces per minute, stable printing speed, suitable for medium and high production capacity.

◆ Precise printing: Precise positioning, clear patterns and texts, and excellent color reproduction.

◆ Multi-specification adaptation: Adjustable parameters, compatible with egg boxes of different sizes and shapes, and quick model change.

◆ Stable and easy to maintain: Wear-resistant, corrosion-resistant components, modular design, low failure rate, easy maintenance.

Product parameter

| Voltage | AC380V/50HZ |

| Total power | 2KW |

| Total weight | 2T |

| External size | 3100 mm×2160 mm×3823 mm |

| Daily production capacity | 700Kg |

| Template size | 800mm×600mm |

| Computer-controlled | PLC+HMI |

Keywords:

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Finished Product Display

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote