Equipment operation and maintenance system

Product Introduction

Product description and feature

◆ Real-time monitoring of equipment throughout the entire factory area: It can be connected to various production equipment in the factory area, collect operating parameters (such as rotational speed, temperature, pressure, etc.) in real time, and visually display the equipment status through a visual interface. Abnormal situations will be immediately reminded by pop-up Windows.

◆ Precise output statistics and analysis: Automatically connect with production line data, calculate the output data of individual equipment, teams and the entire factory in real time, generate daily/weekly/monthly output reports, and support output trend comparison and analysis.

◆ Intelligent fault early warning and diagnosis: Build an early warning model based on equipment operation data to identify potential fault risks in advance and push maintenance suggestions. ◆ Combine historical data to assist in fault location and reduce downtime.

◆ Collaborative management of operation and maintenance tasks: Automatically generate inspection and maintenance tasks based on equipment status, assign them to corresponding positions, track the completion progress, and associate the inventory of spare parts to ensure efficient allocation of operation and maintenance resources.

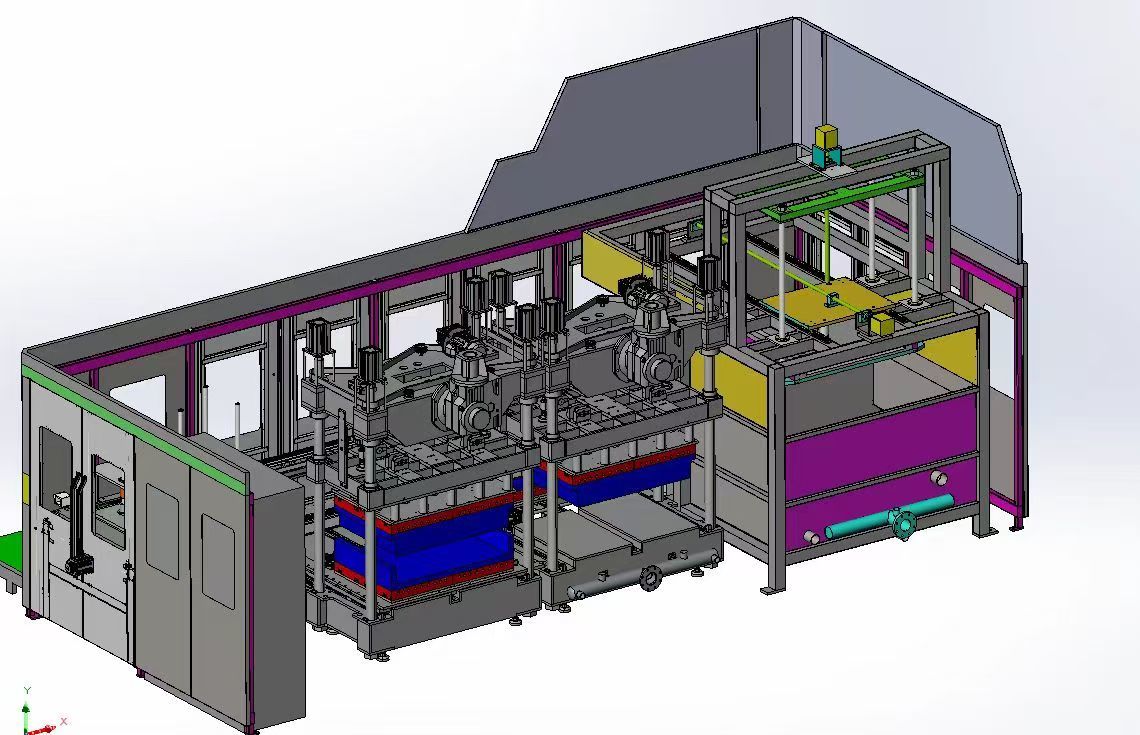

System page display

|

|

|

|

Keywords:

Content update in progress,...

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote