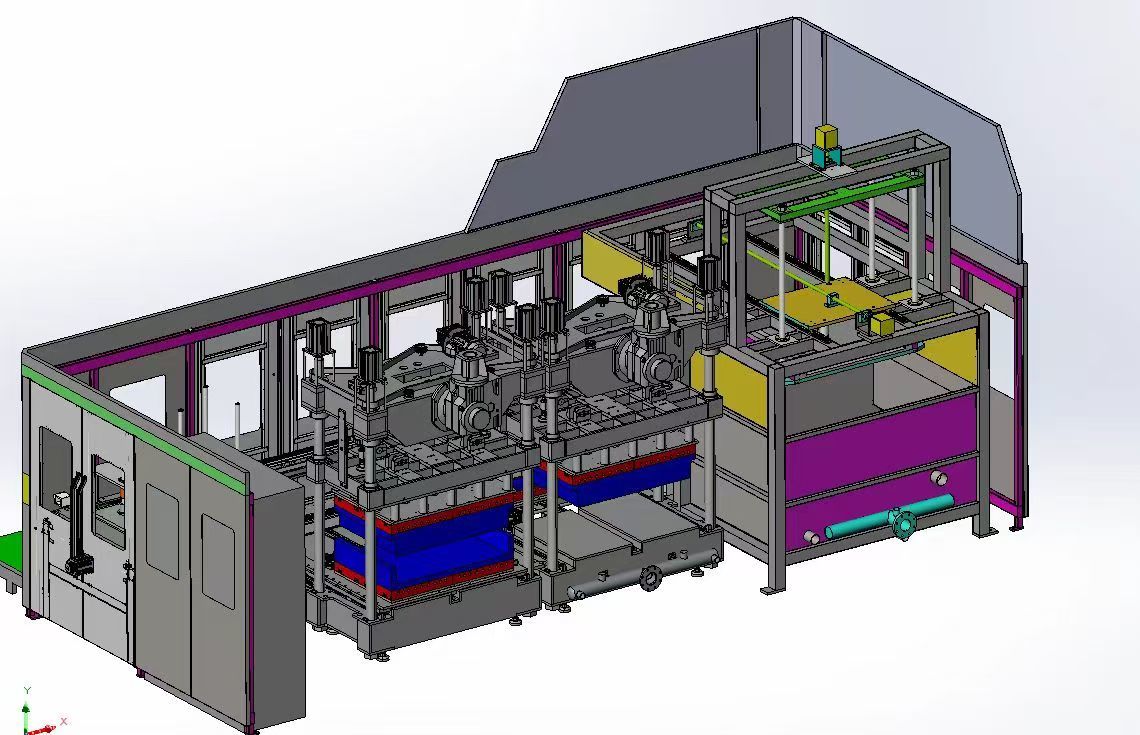

Truss Robot system

Product Introduction

Product description and feature

◆ Precise docking with molding system: Stable mechanical & signal connection with dual-station machine, picking error ≤±1mm, synchronized with molding rhythm.

◆ Efficient picking & placing: Single pick ≤2s, stably grabs various pulp products, accurately places on trolleys, no deformation or falling.

◆ Fully automated: Replaces manual picking, links with molding machine & trolley line, full auto picking-placing, less manual intervention.

◆ Adaptive to dual-station rhythm: Reciprocating speed matches dual-station frequency, cycle time compatible with molding, no stuck waiting.

◆ Reliable safety: Infrared induction & emergency stop, instant stop on obstacles/abnormalities, ensures equipment & product safety.

Keywords:

Content update in progress,...

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote