Full-automatic tableware machine II

Product Introduction

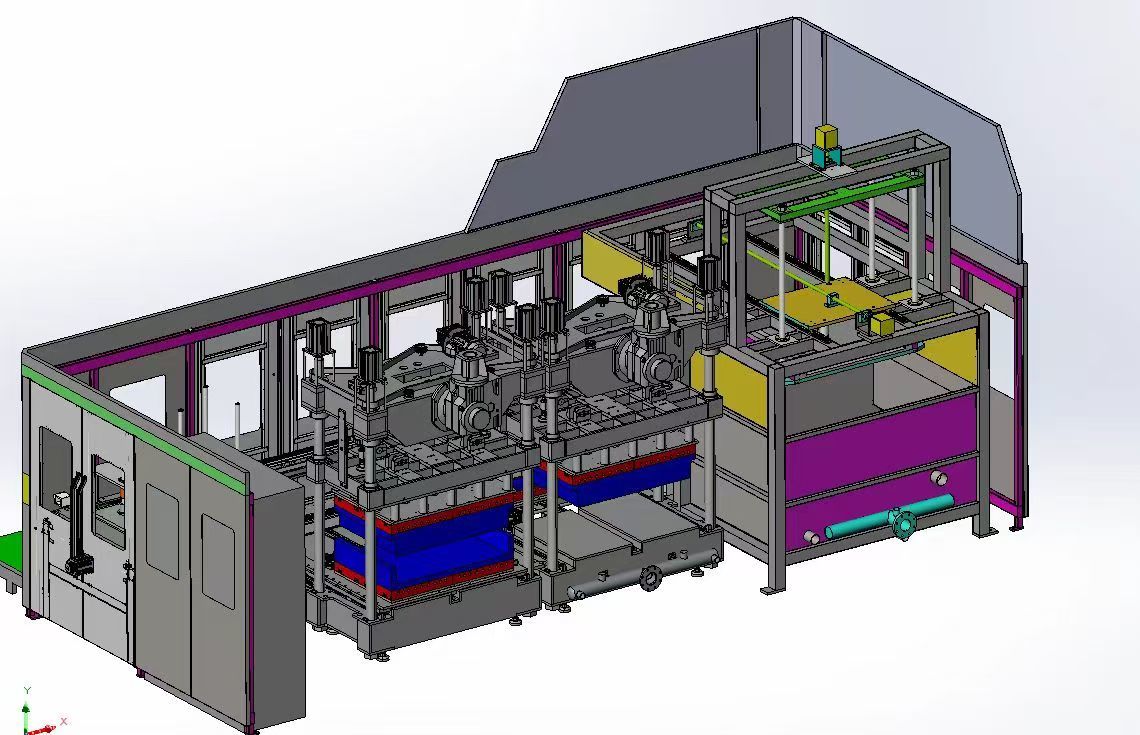

Full-automatic tableware machine II

The Full-automatic Tableware Machine II is a state-of-the-art solution designed for high-efficiency production of disposable tableware, including plates, bowls, and trays. Equipped with fully automated feeding, forming, and stacking systems, it minimizes manual intervention while maximizing output and consistency. Advanced temperature and pressure control ensure precise molding, excellent product quality, and reduced material waste. Ideal for large-scale manufacturing, the machine integrates intelligent monitoring and easy maintenance features, allowing operators to optimize production with minimal downtime. Its robust design and energy-efficient operation make it a reliable choice for modern tableware manufacturers seeking both productivity and sustainability.

Keywords:

Finished product display

Finished product display

Finished product display

Customer Message

Feedback from Hannah, a customer in Frankfurt, Germany

Feedback from Hannah, a customer in Frankfurt, Germany

Q & A

What is the core production process of paper plastic machinery?

Raw material pulping → Mold adsorption molding (wet billet) → Hot pressing shaping (dry pressing) → Edge cutting shaping → Stacking packaging. Wet pressing (integral molding) and dry pressing (transfer molding) are mainstream processes.

What are the specifications for adapting molding machines and molds?

Mold installation plate size/positioning hole distance/vacuum interface type

What are the payment methods and node ratios?

Deposit 50% -40% before shipment -10% after acceptance

What is the division of responsibilities for cross-border transportation?

FOB port delivery or DDP to factory (insurance plus 110%)

EQUIPMENT

Get a Quote