Revolutionizing Dining: The Rise of Tableware Machines in Modern Manufacturing

Aug 06,2025

In recent years, the tableware industry has undergone a significant transformation, driven largely by the integration of advanced machinery into production processes. The rise of the tableware machine—an umbrella term for automated systems used to manufacture plates, bowls, cups, and cutlery—has redefined how tableware is produced, packaged, and delivered to both domestic and global markets.

Traditionally, tableware was manufactured using manual labor and rudimentary tools, which limited efficiency, increased production costs, and often led to inconsistent product quality. However, the growing demand for high-quality, hygienic, and eco-friendly tableware has accelerated the need for more efficient and scalable production methods. This is where the tableware machine plays a crucial role.

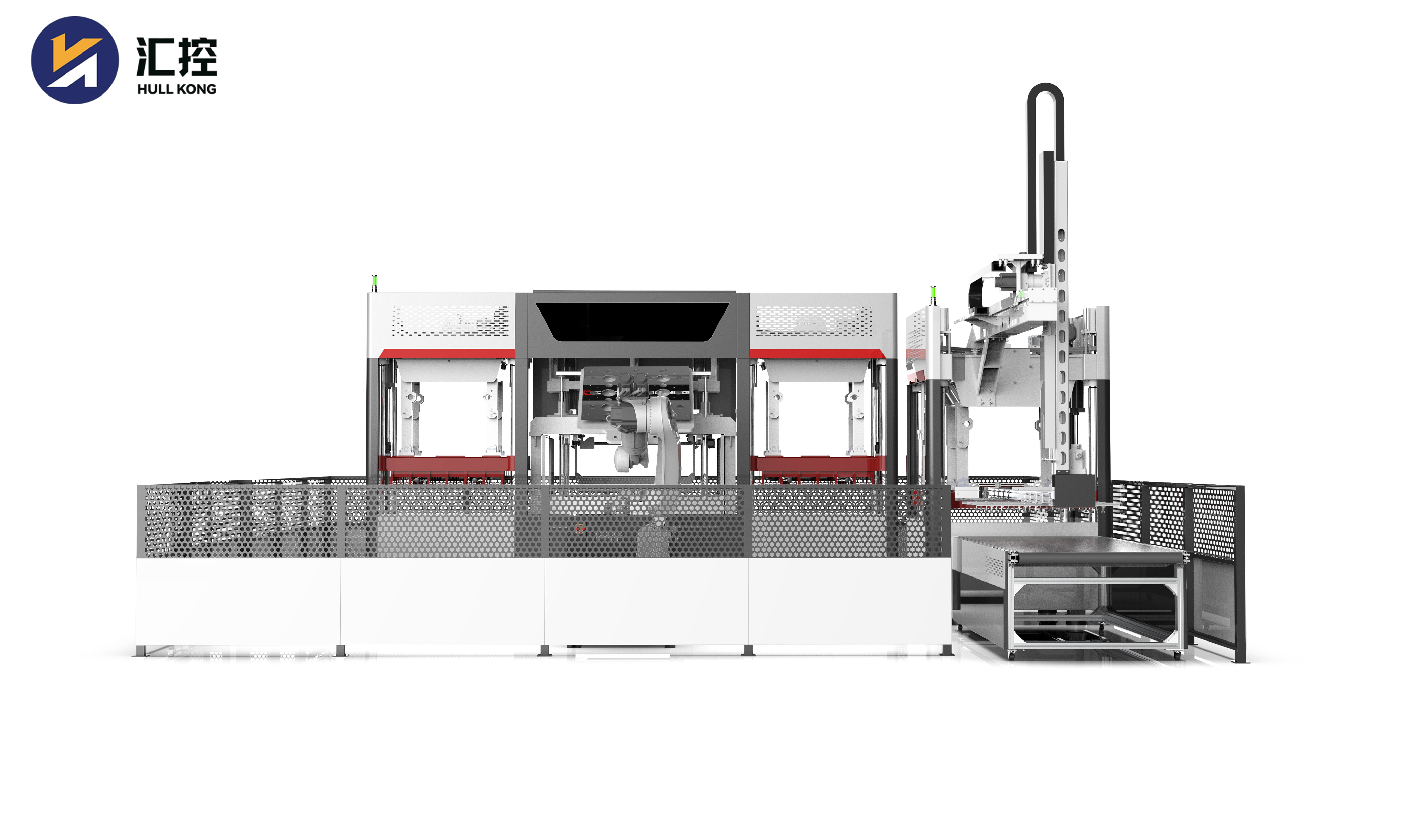

Modern tableware machines integrate a variety of technologies, including hydraulic pressing, thermal forming, injection molding, and CNC cutting. These machines are capable of producing a wide range of materials, such as ceramic, stainless steel, melamine, bamboo fiber, and biodegradable plant-based materials. With the touch of a button, manufacturers can now create hundreds of identical products per hour—each meeting strict quality standards and environmental regulations.

One of the most significant breakthroughs in tableware machine development is the ability to produce biodegradable tableware. In response to the global push toward sustainability, many manufacturers have invested in machines that can mold tableware from raw materials like sugarcane bagasse, wheat straw, and corn starch. These eco-conscious machines not only reduce plastic waste but also meet growing consumer demand for sustainable lifestyle products.

Moreover, automation in tableware machinery enhances workplace safety and reduces dependency on skilled labor, which is often in short supply. Features such as programmable logic controllers (PLCs), smart sensors, and real-time monitoring systems allow manufacturers to optimize production lines, minimize defects, and ensure consistent product quality.

The international market for tableware machines has also expanded rapidly. Countries such as China, Germany, and India have emerged as leading producers and exporters of these machines, catering to a global clientele spanning the hospitality, airline, fast-food, and homeware sectors. Trade shows and exhibitions frequently showcase the latest advancements, allowing manufacturers to stay competitive and informed.

Despite the benefits, challenges remain. High initial investment costs, the need for regular maintenance, and the constant evolution of technology require manufacturers to remain agile and adaptive. Additionally, global regulations regarding food safety and material usage necessitate ongoing compliance efforts.

Looking forward, innovations in artificial intelligence and the Internet of Things (IoT) are expected to further transform the tableware machine industry. Smart factories may soon use machine learning to predict maintenance needs, adjust production speeds based on demand, and even detect flaws in real-time without human intervention.

In conclusion, the tableware machine has become an indispensable component of the modern tableware manufacturing industry. Its impact on efficiency, quality, sustainability, and cost-effectiveness marks a new era of production excellence. As technology continues to evolve, so too will the capabilities and reach of these powerful machines, shaping the future of dining around the world.

PREV: