Development characteristics of pulp molding

Jun 24,2025

Widely applicable in various fields. Pulp molded products have been widely used in food packaging, agricultural product packaging, and industrial production. The development of pulp molding abroad mainly has the following characteristics: product packaging, cultural and creative product packaging, gift packaging, and other fields. Among them, pulp molding industrial packaging products have been applied in cushioning packaging for the automotive industry, electronic products, hardware appliances, medical equipment, household goods, and office products.

(1)Widely applicable in various fields. Pulp molded products have been widely used in food packaging, agricultural product packaging, and industrial production. The development of pulp molding abroad mainly has the following characteristics: product packaging, cultural and creative product packaging, gift packaging, and other fields. Among them, pulp molding industrial packaging products have been applied in cushioning packaging for the automotive industry, electronic products, hardware appliances, medical equipment, household goods, and office products.

(2)The processing technology is constantly innovating, and the application scenarios of products are constantly expanding. In addition to the traditional thousand pressure process, technologies such as wet pressing, semi dry pressing, high-quality dry pressing, and waterless dry pressing have rapidly emerged to meet the rapidly developing market demand.

(3)Product design standards have a high degree of standardization and modularization. In the production of pulp molded products, mold cost is one of the important costs. Foreign manufacturers pay attention to the wide applicability and strong universality in the design of pulp molded products, such as designing universal shaped lining plates, corner protectors, partitions, etc., which can be used to package various types of interior products. Due to its large production volume and high utilization rate of molds, the amortization cost of molds is greatly reduced.

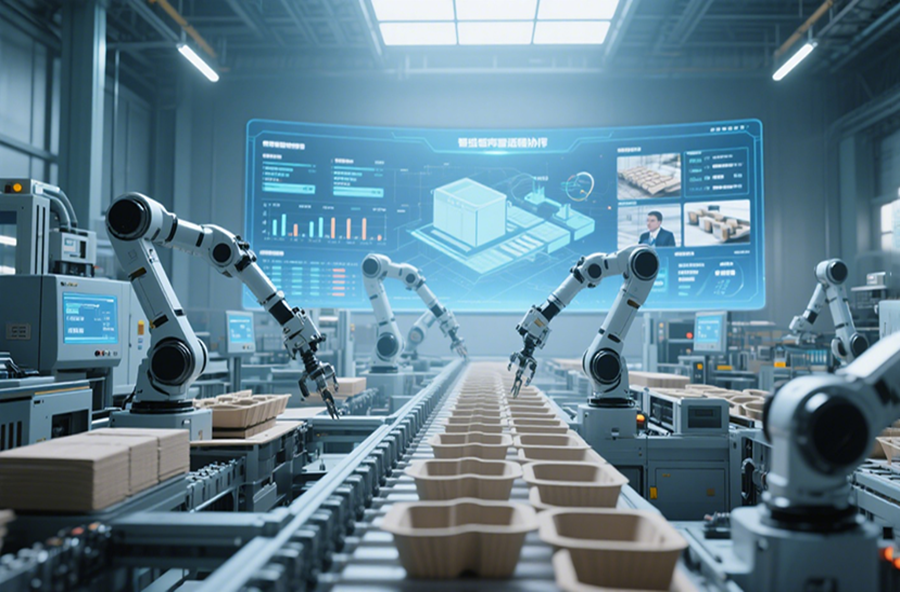

(4)Rapidly developing intelligent, automated, and remotely collaborative pulp molding production equipment, reducing manpower demand, and achieving efficient, energy-saving, intelligent, modular, standardized, and specialized pulp molding production has become the direction for the development of the pulp molding industry.

PREV:

Related News