PRODUCTS

Has Been Deeply Engaged Inthe Intelligent Manufacturing Industry For Eight Years, The Company Hasestablished A Strategic Partnership With Siemens.

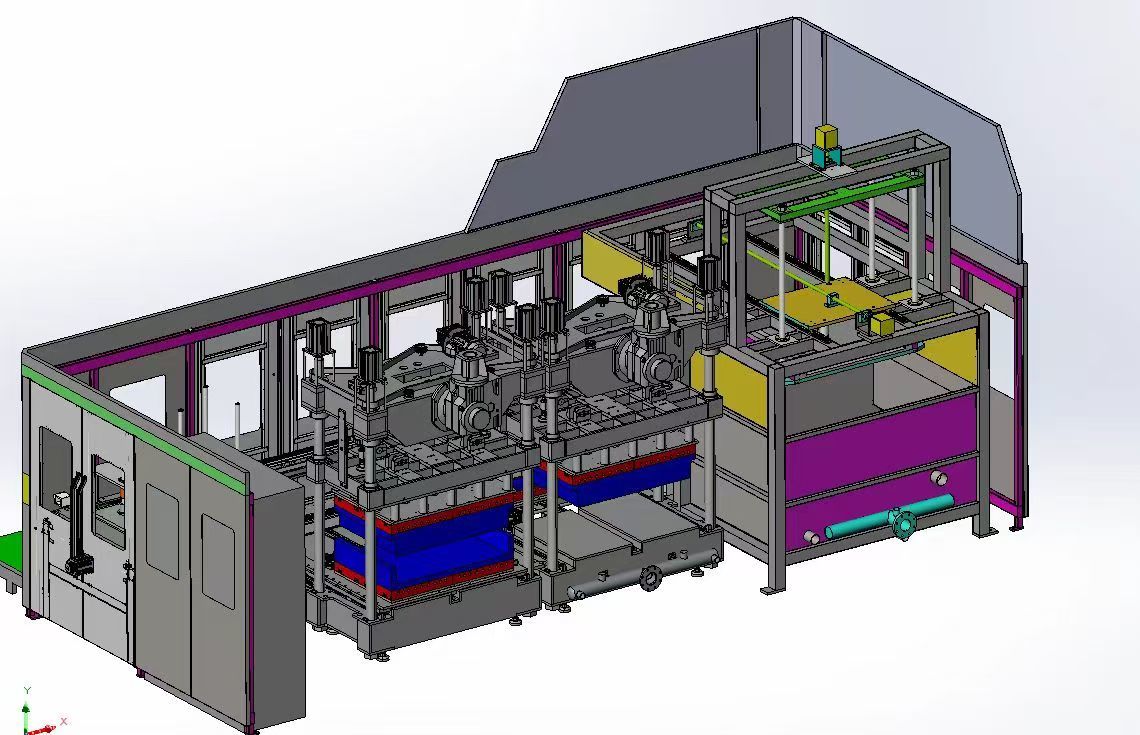

Edge-Cutting Stacker

whole machine adopts a fully servo control system, which is fast in speed and high in accuracy. The edge cutting machine uses a servo linkage mechanism to operate, automatically lubricate and lubricate, and digitally adjust the mold opening height and closing height. Due to the use of digital position cutting, it effectively protects and extends the service life of the cutting die.

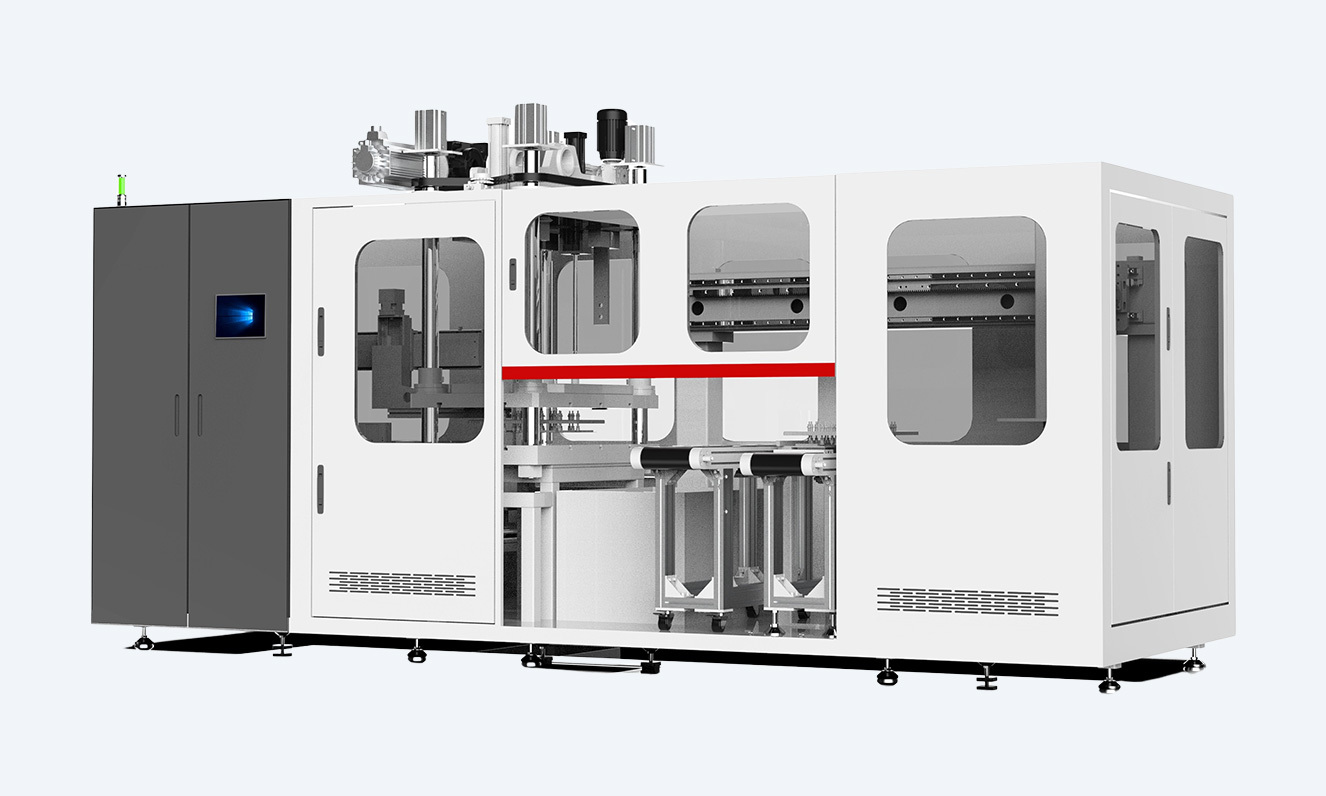

Tableware machine

The working principle of the rotary drum forming machine is to send the prepared slurry to the slurry tank of the forming machine through the slurry pump. The rotary drum machine is started to operate, and the forming mold keeps rotating with the rotary drum. When the slurry level reaches, the vacuum suction valve is opened to suck the slurry. When the forming mold rotates to release the slurry, the pulp is adsorbed onto the mold mesh through vacuum filtration to form a wet paper mold base. The wet paper mold continues to dehydrate during the rotation of the drum, while hot air is sent from the upper cover for preheating.

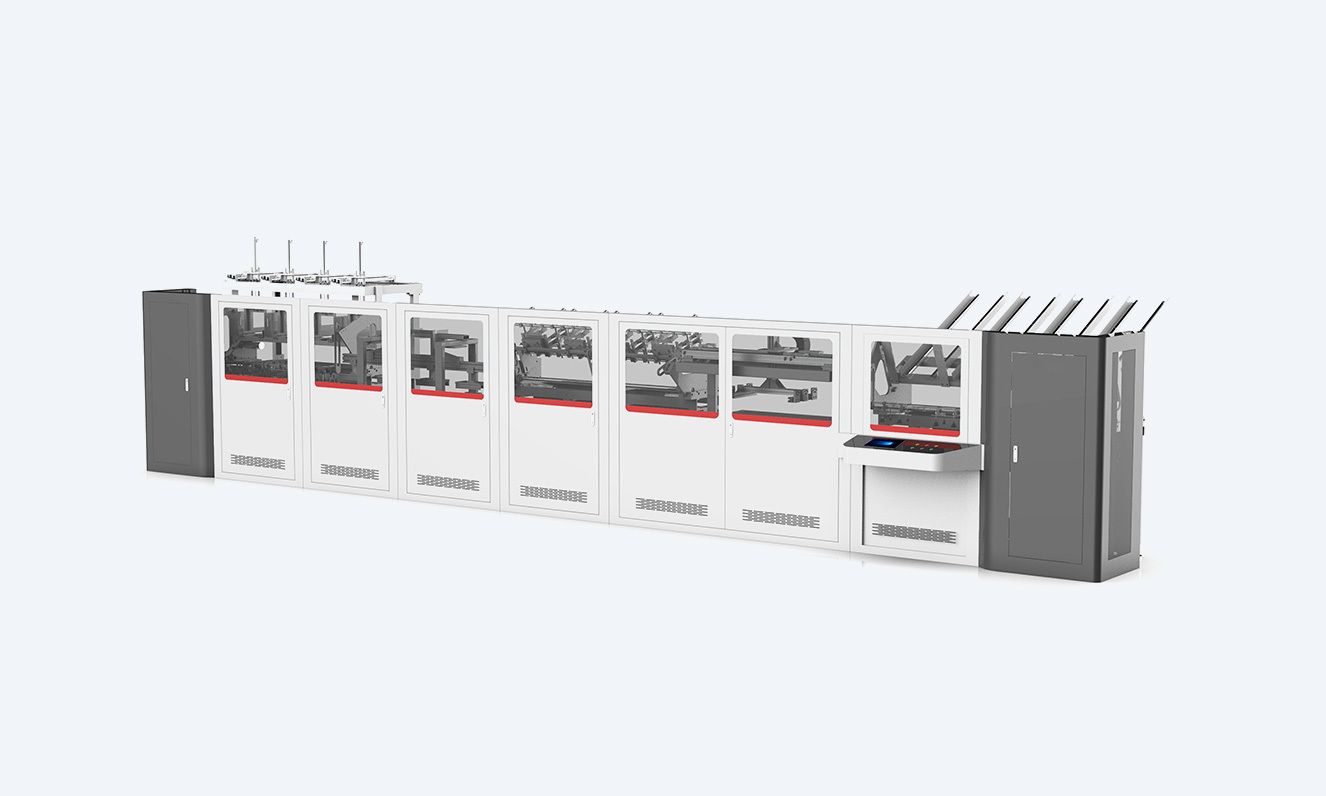

Egg Box Prduction Line

Introduction: The working principle of the rotary drum forming machine is to send the prepared slurry to the slurry tank of the forming machine through the slurry pump. The rotary drum machine is started to operate, and the forming mold keeps rotating with the rotary drum.

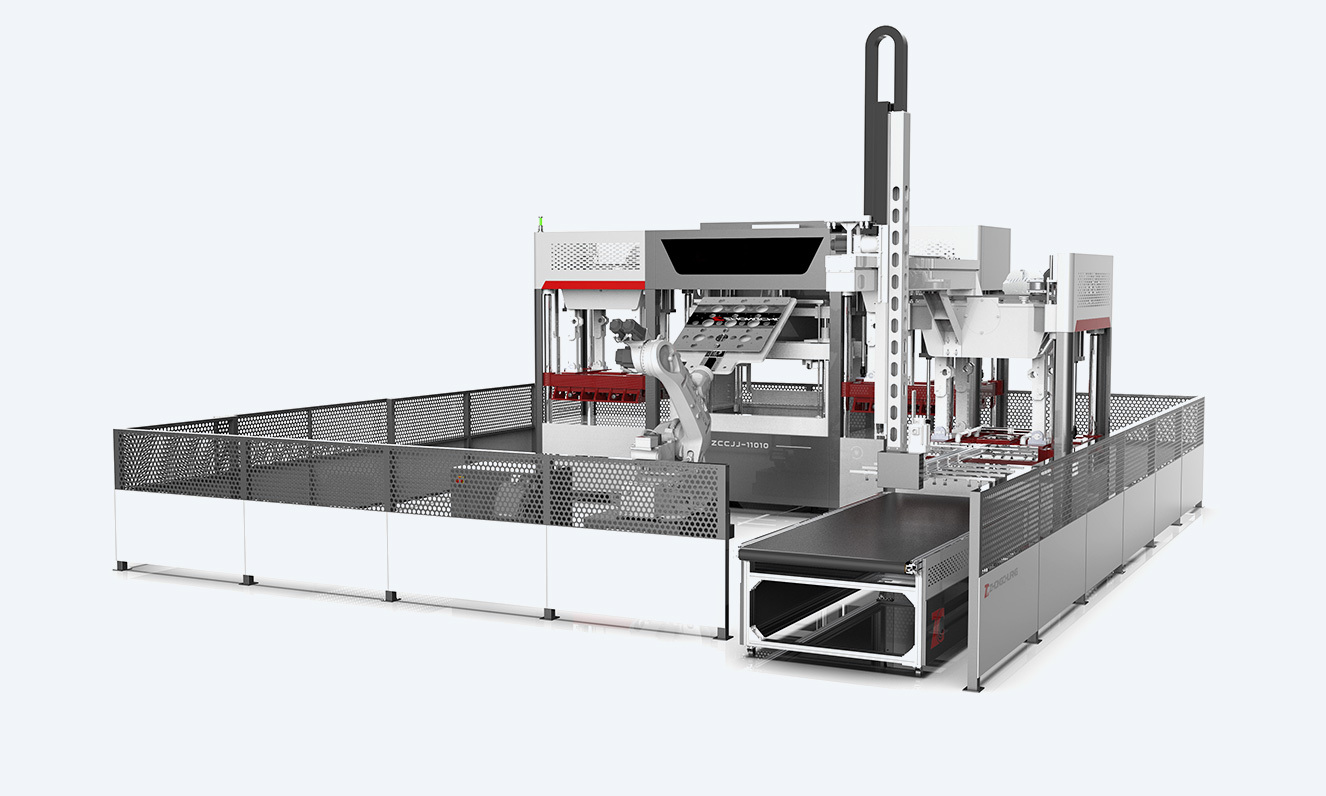

Hot Pressing Forming Line

The equipment adopts the servo connecting rod hot pressing + removal method, featuring high speed, high precision, uniform pressure, and a product qualification rate of 99%. Its production capacity is five times that of traditional manual hot presses, reaching 2,280 pieces (12 pieces) per hour. It is convenient to use, safe and reliable.

Labeling Machine

The equipment adopts a servo+mechanical transmission mode, with a simple mechanical mechanism, easy operation, and high degree of automation. It can label 2 products (10 or 12 pieces) at the same time.

ABOUT FULLKONG

EMPOWERING THE INDUSTRY WITH TECHNOLOGY AND CREATING VALUE WITH SERVICES

Huikong Company is a strategic subsidiary or department under the overseas office of Zhongchuang Group (a Chinese enterprise specializing in research and development of paper and plastic equipment and technology manufacturing), responsible for market expansion, sales, and services in overseas markets. Its core business area and strategic focus are the global paper and plastic equipment market outside Chinese Mainland.

Learn More →Franchise Authorization And Agency

Sales In 2024

Patented Technologies

Powerful core technology

Professional technical development team, Focus on product development and testing

Professional technical support

Strong technological strength, Advanced and sophisticated processing and testing equipment

comprehensive service system

Products with high-tech content, A comprehensive after-sales service system

Powerful core technology

Survive with high-end quality, Seeking development through technological innovation

THE COMPANY HASESTABLISHED A STRATEGIC PARTNERSHIP WITH SIEMENS

Relying on the continuous trust of customers and partners,the company hasestablished a strategic partnership with Siemens, driven by innovation to achieveleapfrog development, and has now grown into a leading enterprise in the industry.

Learn More →THERE ARE 21 PATENT TECHNOLOGIES AND 7 FRANCHISES AND AGENCY SERVICES

The company has obtained the following national and international standard certifications: ISO9001:2015、ISO-14001:2015、ISO-45001: In 2015, the intellectual property management system was standardized, and these certifications are a reflection of Ruishi's management standards and high-quality products. The Ruishi brand (Rsee) machine vision light source has become one of the most well-known brands in China.

Learn More →GET IN TOUCH

ARE YOU LOOKING FOR PRODUCTS OR EQUIPMENTS SOLUTIONS

We Are Committed To Providing You With The Highest Quality Products And Services. If You Have Any Questions Or Need More Information, Please Feel Free To Contact Us At Any Time

VIDEO OF EQUIPMENT OPERATION

Empowering The Industry With Technology And Creating Value With Services

With over a decade of expertise, Huikong (a subsidiary of Zhongchuang Group) specializes in the R&D and manufacturing of paper plastic machinery, actively contributing to the industry's evolution.

We possess a deep understanding of diverse production needs and technical challenges, delivering proven solutions. Through strong industry-university-research collaborations with Fuzhou University and Hunan University of Technology, we continuously advance our R&D to embrace the latest technological trends.

Our continuous innovations in molding process optimization, automation control, and energy-saving technologies ensure our equipment is smarter, more efficient, and environmentally friendly.

COOPERATIVE PARTNER

Has Been Deeply Engaged Inthe Intelligent Manufacturing Industry For Eight Years, The Company Hasestablished A Strategic Partnership With Siemens.

BLOG & MEDIA

Pay Attention To Fullkong, Grasp The Industry Direction, Keep Up With The Pulse Of The Times