Products

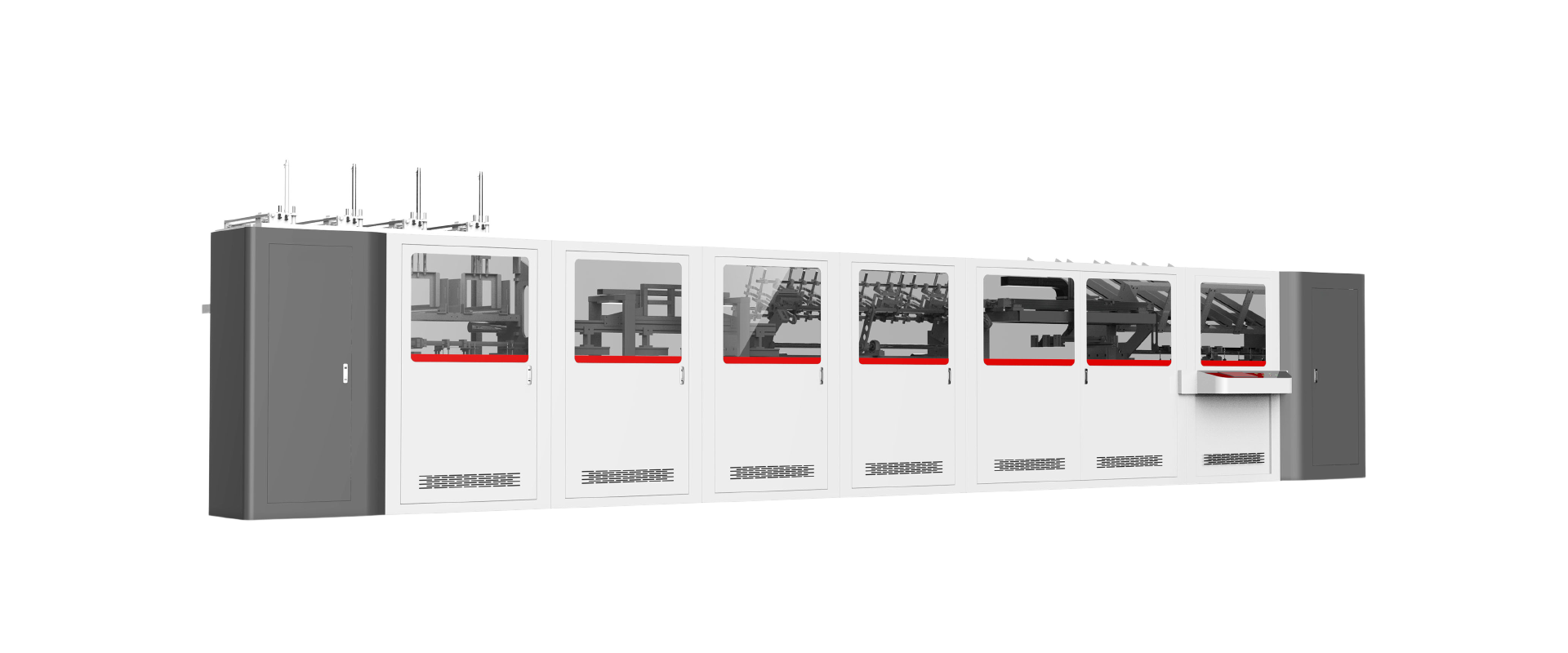

whole machine adopts a fully servo control system, which is fast in speed and high in accuracy. The edge cutting machine uses a servo linkage mechanism to operate, automatically lubricate and lubricate, and digitally adjust the mold opening height and closing height. Due to the use of digital position cutting, it effectively protects and extends the service life of the cutting die.

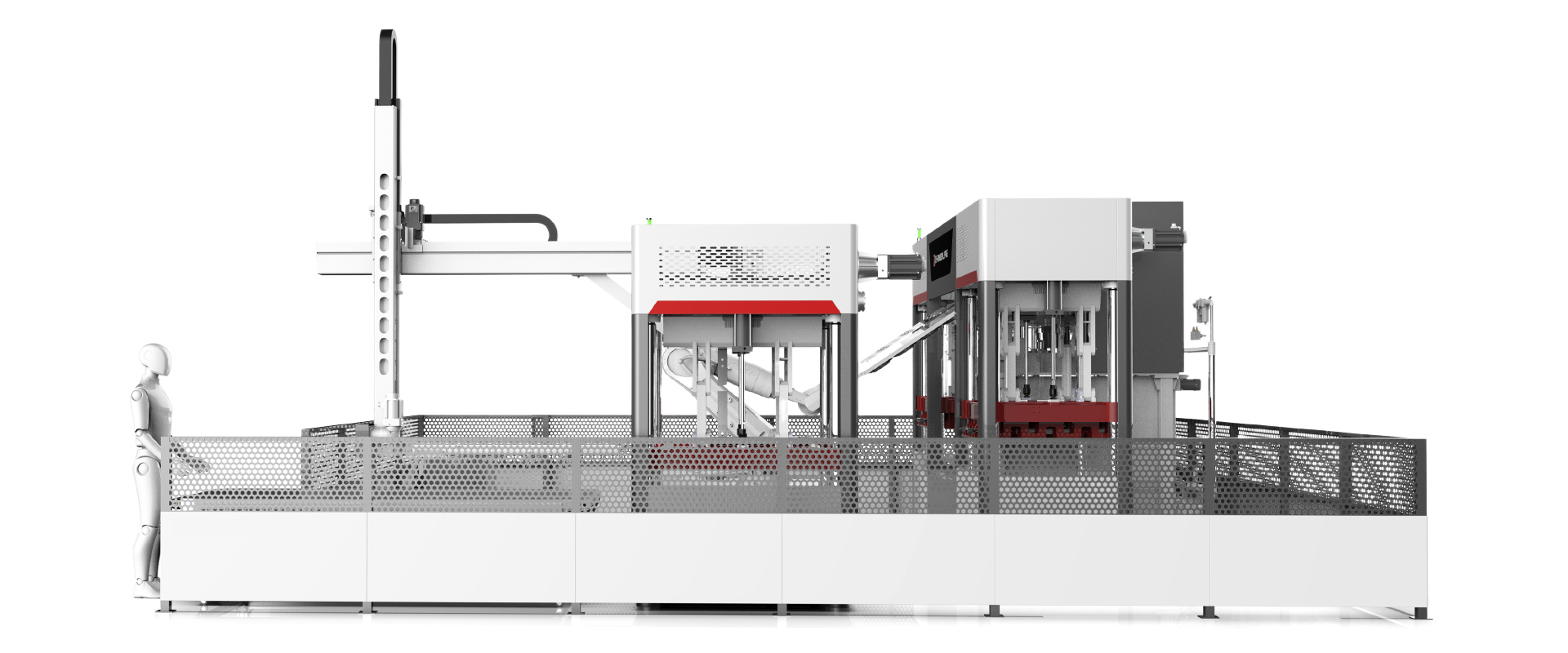

The fully automatic robot intelligent tableware machine has the advantages of precise control, flexible, precise, and stable production operation, with a single machine output of 900-1100kg/d. It is mainly suitable for producing disposable pulp molded tableware, plates, food boxes, high-end industrial shock resistant packaging and other products.

Introduction: The working principle of the rotary drum forming machine is to send the prepared slurry to the slurry tank of the forming machine through the slurry pump. The rotary drum machine is started to operate, and the forming mold keeps rotating with the rotary drum.

The equipment adopts the servo connecting rod hot pressing + removal method, featuring high speed, high precision, uniform pressure, and a product qualification rate of 99%. Its production capacity is five times that of traditional manual hot presses, reaching 2,280 pieces (12 pieces) per hour. It is convenient to use, safe and reliable.

The equipment adopts a servo+mechanical transmission mode, with a simple mechanical mechanism, easy operation, and high degree of automation. It can label 2 products (10 or 12 pieces) at the same time.

Egg carton inner printing machine

High-speed and efficient printing: 50-60 pieces per minute, stable printing speed, suitable for medium and high production capacity.

High-quality industrial packaging machine I

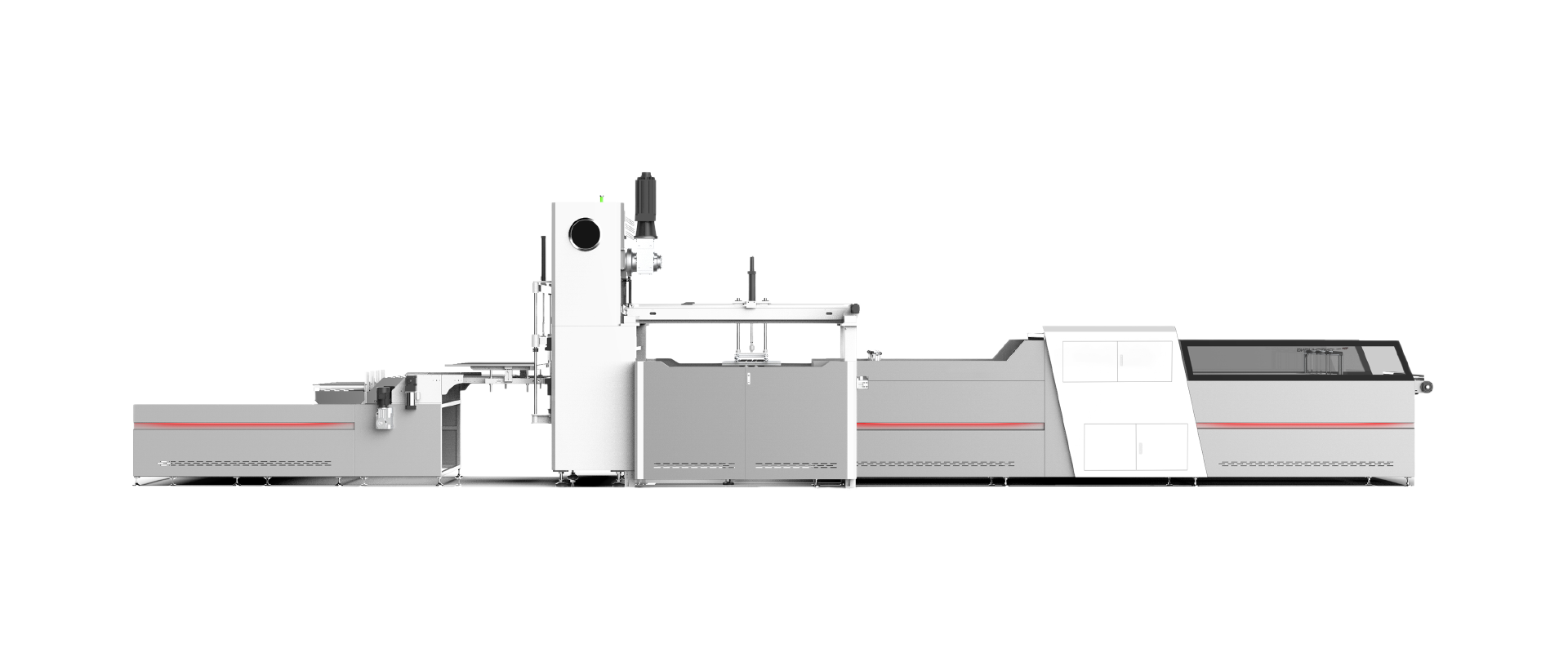

The device adopts a linear structure, minimizing space requirements to the greatest extent.

High-quality industrial packaging machine II

Precise small draft angle forming: Servo linkage drive, high precision, stable production, error ±0.3mm.

Economical and efficient: suitable for small and medium-sized production.

Precise docking with molding system: Stable mechanical & signal connection with dual-station machine, picking error ≤±1mm, synchronized with molding rhythm.

Full-automatic tableware machine II

1100*800 wet press forming machine Linear structure 1 forming station +l hot pressing stationThe slurry is scooped and formed.Low draft angles can be produced

Equipment operation and maintenance system

Real-time monitoring of equipment throughout the entire factory area: It can be connected to various production equipment in the factory area, collect operating parameters (such as rotational speed, temperature, pressure, etc.) in real time, and visually display the equipment status through a visual interface. Abnormal situations will be immediately reminded by pop-up Windows.